Operation and Maintenance Instruction

General Safety Precautions

HYDAC Filtertechnik GmbH

en

Page 36

BEWA OLF15-60 10bar 3255361-01a en.doc

2005-08-25

The hoses and connection fittings are to be checked daily for leakage (visual check). The

electrical components of the OLF are to also be regularly checked (visual check once a

month). Any loose connections or damaged cables are to be replaced immediately.

1.7 Training and Instruction of Personnel

•

The OLF may only be operated by properly trained and instructed personnel.

•

The areas of responsibility of your staff must be established in a clear-cut manner.

•

Staff undergoing training may not use the OLF unless supervised by an experienced staff

member.

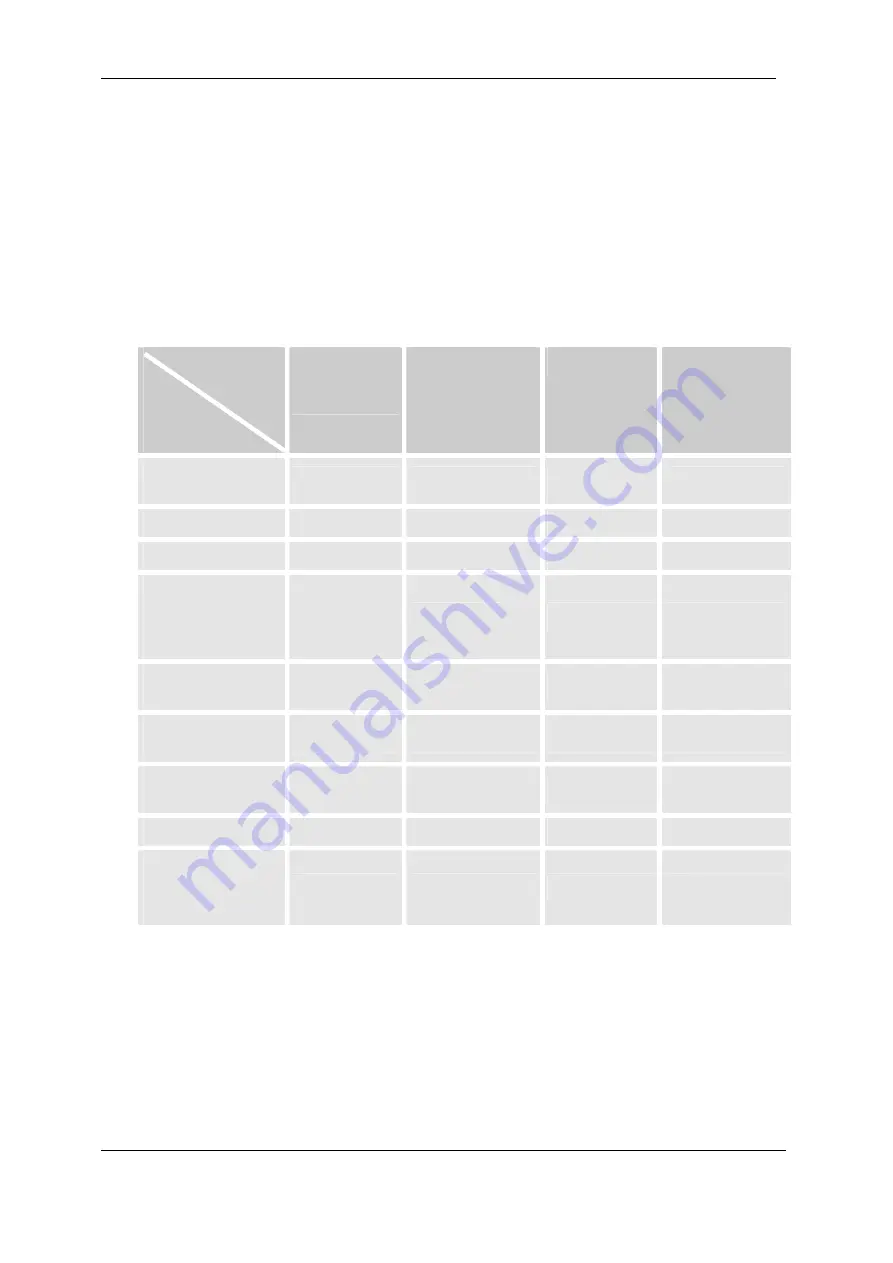

Individuals

Activity

Individuals

undergoing

training

Individuals with

technical

training/

engineering

background

Electrician

Supervisor

with the

appropriate

authority

Packing

Transportation

X

X

X

Commissioning

X

X

X

Operation

X

X

X

X

Troubleshooting/

locating the

source of

malfunction

X

X

X

Remedying of

mechanical faults

X

X

Remedying of

electrical faults

X

X

Maintenance and

servicing

X

X

X

X

Repair work

X

Shutdown/

decommissioning

Storage

X

X

X

X

1.8 Safety Measures to Be Followed in Normal Operation

Do not operate the OLF unless all the protective safety devices function properly.

The unit is to be checked once a day for external damage and the proper functioning of the

safety devices.