Pg 4.19

S23H

SECTION 4, ELECTRICAL SYSTEM

CONTROL PANEL & COMPONENTS

The S-23 bandsaw, with the "H" option, has been designed to provide the operator with a simple to use

interface that controls all saw functions. The electrical system of the S-23 with the "H" option provides power to

the blade drive motor at the required voltage for the motor. The incoming power from source is provided to the

blade motor by means of a motor contactor and a motor overload. The contactor switches the power to the motor

and the overload provides protection from excessive current draw. The contactor overload is set to automatic at

the factory and provides quick reset if the overload "trips". All of the switches that the operator uses to operate

the saw are run with 120 Volts A.C. This control system is fed 120 Volts from a transformer that steps down the

"line" voltage to 120 Volts. The control wiring is protected by means of a fuse that is rated for 1.5 Amperes. The

following components make up the control wiring.

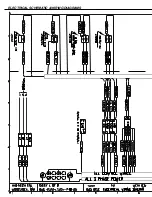

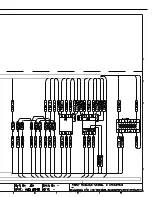

Control panel layout.

Electrical component layout.

Transformer

Fuses

Overloads

Contactors

Ground, l1, L2,

L3 terminals.

Head down

limit switch

Summary of Contents for S-23H

Page 1: ...I N B A N D S A W T E C H N O L O G Y OPERATIONS MAINTENANCE M A N UA L ...

Page 3: ...THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 6: ...SECTION 1 INSTALLATION SECTION 1 INSTALLATION ...

Page 7: ...SECTION 1 INSTALLATION ...

Page 12: ...SECTION 2 OPERATING INSTRUCTIONS SECTION 2 OPERATING INSTRUCTIONS ...

Page 13: ...SECTION 2 OPERATING INSTRUCTIONS ...

Page 19: ...THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 20: ...SECTION 3 MAINTENANCE AND TROUBLE SHOOTING SECTION 3 MAINTENANCE AND TROUBLE SHOOTING ...

Page 21: ...SECTION 3 MAINTENANCE AND TROUBLE SHOOTING ...

Page 28: ...Pg 3 17 S23H SERVICE RECORD NOTES DATE SERVICED BY COMMENTS ...

Page 29: ...THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 30: ...SECTION 4 ELECTRICAL SYSTEM SECTION 4 ELECTRICAL SYSTEM ...

Page 31: ...SECTION 4 ELECTRICAL SYSTEM ...

Page 35: ...ELECTRICAL SCHEMATIC WIRING DIAGRAMS ...

Page 36: ......

Page 37: ...ELECTRICAL SCHEMATIC WIRING DIAGRAMS ...

Page 38: ......

Page 39: ...THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 40: ...SECTION 5 HYDRAULIC SYSTEM SECTION 5 HYDRAULIC SYSTEM ...

Page 41: ...SECTION 5 HYDRAULIC SYSTEM ...

Page 43: ...Pg 5 28 S22 23H CYLINDER ASSEMBLIES Piston assemblies Gland assemblies ...

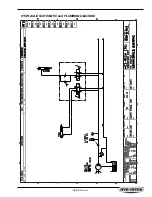

Page 44: ...Pg 5 29 S22 23H HYDRAULIC SCHEMATIC and PLUMBING DIAGRAM ...

Page 45: ...Pg 5 30 S22 23H ...

Page 46: ...SECTION 6 MECHANICAL ASSEMBLIES SECTION 6 MECHANICAL ASSEMBLIES ...

Page 47: ...SECTION 6 MECHANICAL ASSEMBLIES ...

Page 48: ...Pg 6 31 S23H 2001a GUIDE ARM CARBIDE ASSEMBLIES SECTION 6 MECHANICAL ASSEMBLIES ...

Page 49: ...Pg 6 32 S23H 2001a BLADE DRIVE ASSEMBLY ...

Page 51: ...Pg 6 34 S23H 2001a HM4A GEAR BOX ASSEMBLY ...

Page 52: ...Pg 6 35 S23H 2001a IDLERWHEEL ASSEMBLY 01 2345 1 345 1 6 7809 849 59 9 3 01 1 ...

Page 53: ...Pg 6 36 S23H 2001a BLADE BRUSH ASSEMBLY ...

Page 54: ...Pg 6 37 S23H 2001a COUNTER BALANCE SPRINGASSEMBLY ...

Page 55: ...Pg 6 38 S23H 2001a PIVOT LINK ASSEMBLY ...

Page 56: ...Pg 6 39 S23H 2001a 0 1 Pivot link parts list ...

Page 57: ...Pg 6 40 S23H 2001a FRONTVISE ASSEMBLY ...

Page 58: ...Pg 6 41 S23H 2001a HYDRAULIC POWER PACK ...

Page 61: ...THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 62: ...SECTION 7 OPTIONAL ASSEMBLIES SECTION 7 OPTIONAL ASSEMBLIES ...

Page 63: ...SECTION 7 OPTIONAL ASSEMBLIES ...

Page 64: ...Pg 7 45 S23H SECTION 7 OPTIONAL ASSEMBLIES WORK STOP ...

Page 67: ...Pg 7 48 S23H 30O MITRE CUTTING ...

Page 68: ...SECTION 8 SPECIFICATIONS SECTION 8 SPECIFICATIONS ...

Page 69: ...SECTION 8 SPECIFICATIONS ...

Page 71: ...Pg 8 50 S23H LAYOUT DRAWINGS ...

Page 72: ...Pg 8 51 S23H ...

Page 73: ...THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 74: ...SECTION 9 WARRANTY SECTION 9 WARRANTY ...

Page 75: ...SECTION 9 WARRANTY ...