START-UP

Before starting the machine, remove any

wrenches or setting tools.

Keep the safety guard in place for all work.

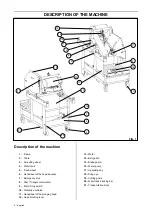

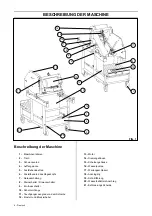

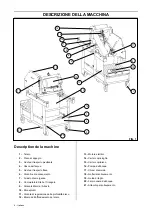

The machine is delivered with an uninstalled head

advancement wheel (6) [FIG.1], packed in the accessory

box. Install this wheel on its shaft [FIG.4].

[FIG.4]

For start-up and after transport, the machine must be

unbridled:

•

Loosen screws (A) until casters are in contact with

the guide bars [FIG.2]

Next,

•

Fill water tank (4) [FIG.1]. (Water pump starts

automatically with motor).

•

Place the material on table (2) according to desired

cut, using cutting guide (18) and rulers [FIG.1].

•

Start

motor:

For heat engine machines:

Æ

Start motor according to manufacturer’s instruction manual.

Æ

Allow motor to warm up.

For electric motor machines:

Æ

Start machine by pressing the “I” button

of the contactor or by turning the contactor

(9) to the “I” position. Turn switch (8) to “Y”

position then to

. [FIG.1]

Next,

•

Loosen control handle (12) and turn wheel (11) [FIG.1].

•

Lower saw to desired cutting depth as indicated on

graduated scale. Come down slowly so as to avoid

stalling the motor.

•

When the desired depth has been reached, retighten

the control handle (12).

•

Gently move the cutting head forward using the

wheel (6) [FIG.1]. Advance slowly so as to avoid

stalling the motor.

•

Once the cut has been made, use wheel (6).to gently

back the head up to its maximum rear position.

•

Stop motor (see details in next section)

Before handling the cut material in

any way, stop the motor and wait for

the disc to come to a full stop.

Sound level at the workstation may

exceed 85db (A) and therefore

personal protection equipment must

be worn.

Heat engine machines may not be

operated in a confined space unless

there is sufficient ventilation.

The exhaust gasses contain carbon

monoxide. Exposure to this toxic gas

can cause loss of consciousness

and death.

Stop

Stop the motor

Heat engine: switch off at machine control panel

Electric motor: press red emergency stop

button (7) or turn contactor (9) to position “O”.

Then turn switch (8) to position Y [FIG.1].

9 - English