F2.8

Part. N. 8000 H4704 (07-2010)

11

12

MAINTENANCE

Remove:

4.

Digital rev meter

•

Stroboscopic lamp

•

Install:

5.

Timing mark access screw (together with O-ring)

•

MEASURING COMPRESSION PRESSURE

An insufficient compression pressure would negatively affect

•

performance.

Measure:

1.

Valve clearance

•

Not conforming to specs

•

Adjust.

Refer to "

•

VALVE CLEARANCE ADJUSTMENT

" on page

3-4.

Start engine,

2.

warm it up a few minutes, then stop it.

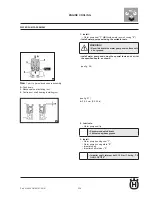

Disconnect:

3.

Coolant temperature sensor connector "

•

1

";

Spark plug cap "

•

2

".

(see fig.11)

Remove:

4.

Spark plug.

•

Install:

5.

Extension "

•

1

";

Compression gauge "

•

2

".

(see fig.12)

WARNING!

Before removing the spark plug, remove any

•

impurities built up inside its seat with compres-

sed air to avoid they enter the cylinder.

Standard compression pressure (at sea level): 550

•

kPa/600 rpm (78.2 psi/600 rpm) (5.5 kgf/cm2/600

rpm)

Minimum-maximum: 480-620 kPa (68.3-88.2 psi)

•

(4.8-6.2 kgf/cm2)

Measure:

6.

Compression pressure.

•

Not conforming to specs

Refer to operations (

c

) and (

d

).

Take ignition switch to "ON".

a.

With throttle fully open, start engine and allow pressure reading

b.

on compression gauge to stabilise.

Summary of Contents for SMS4

Page 1: ...Workshop Manual TE 125 2011 SMS4 2011 Part N 8000H4704 07 2010 ...

Page 6: ......

Page 7: ...A 1 A Part N 8000 H4704 07 2010 GENERAL INFORMATION Section ...

Page 14: ......

Page 15: ...b 1 Part N 8000 H4704 07 2010 b IMPORTANT NOTICES Section ...

Page 17: ...F 1 Part N 8000 H4704 07 2010 TECHNICAL DATA F Section ...

Page 35: ......

Page 36: ......

Page 37: ...F1 1 Part N 8000 H4704 07 2010 F1 ENGINE OVERHAUL Section ...

Page 109: ...F2 1 Part N 8000 H4704 07 2010 F2 MAINTENANCE Section ...

Page 121: ...F3 1 Part N 8000 H4704 07 2010 F3 ENGINE COOLING Section ...

Page 131: ...F4 1 Part N 8000 H4704 07 2010 F4 CARBURETTOR Section ...

Page 132: ...F4 2 Part N 8000 H4704 07 2010 CARBURETTOR CARBURETTOR ...