Summary of Contents for SMS4

Page 1: ...Workshop Manual TE 125 2011 SMS4 2011 Part N 8000H4704 07 2010 ...

Page 6: ......

Page 7: ...A 1 A Part N 8000 H4704 07 2010 GENERAL INFORMATION Section ...

Page 14: ......

Page 15: ...b 1 Part N 8000 H4704 07 2010 b IMPORTANT NOTICES Section ...

Page 17: ...F 1 Part N 8000 H4704 07 2010 TECHNICAL DATA F Section ...

Page 35: ......

Page 36: ......

Page 37: ...F1 1 Part N 8000 H4704 07 2010 F1 ENGINE OVERHAUL Section ...

Page 109: ...F2 1 Part N 8000 H4704 07 2010 F2 MAINTENANCE Section ...

Page 121: ...F3 1 Part N 8000 H4704 07 2010 F3 ENGINE COOLING Section ...

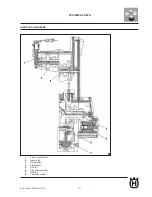

Page 131: ...F4 1 Part N 8000 H4704 07 2010 F4 CARBURETTOR Section ...

Page 132: ...F4 2 Part N 8000 H4704 07 2010 CARBURETTOR CARBURETTOR ...