INSTALLATION

36

Framed Stand-Alone Specialty Shapes

NOTE:

If a Decorative Sill Cover was ordered, refer to page 39.

Stand-alone specialty shape shutters are installed independently of standard shutters.

1.

Place the frame in or over the opening and center. Make sure the bottom frame is level.

2.

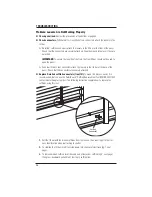

Attach the frame with two screws through the curved portion of the frame.

➤

Screws should be placed in the top left and top right of the curve as illustrated below.

➤

Do not overtighten the screws — doing so could distort the shape.

3.

Place the panel into the frame by lining up the hinge barrels and inserting the hinge pins.

Close the top and sides by depressing the specialty shape’s Duracatch

™

spring-loaded

plungers into the grooves in the frame.

4.

Move the bottom of the frame left or right to create the proper gaps around the panel.

➤

Mark the bottom frame location where the proper gaps are created.

➤

Remove the panel from the frame.

5.

Move the bottom frame to align it with the mark, and drive a screw through the middle of the

bottom frame to hold it in the correct position.

6.

Place the panel back into the frame and double-check that it fits properly.

7.

Remove the panel from the frame and set all remaining screws, being careful not to

overtighten.

8.

Place the panel into the frame. Adjust plunger depth if necessary to provide a good fit in

the frame.

➤

If fit is too tight, push in on the plunger and rotate clockwise to retract the plunger.

➤

If fit is too loose, push in and rotate the plunger counterclockwise to extend it.

9.

Perform any necessary finish work to complete the installation (see page 42).

First Two Screw Locations

Framed Stand-Alone Specialty Shapes