NOTE:

The running position of the transducer is now completely adjustable. Subsequent adjustment may be

necessary to tweak the installation after high speed testing.

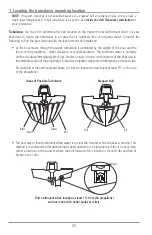

To adjust the running position of the transducer:

The transducer mounting bracket allows height and tilt adjustment, while the pivot bolt allows angular

adjustment. These adjustments will help reduce cavitation. Initially, adjust the transducer as described in the

following paragraphs. Further adjustment may be necessary to refine the installation after high-speed testing.

1. First, adjust the pivot angle of the transducer body, so it is parallel with the length of the hull of

the boat.

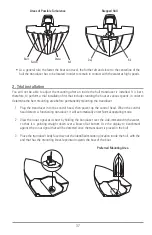

2. Fully tighten the two pivot screws, using the supplied Allen wrench. Access to the pivot screws

is provided by the lower holes in the side of the mounting bracket. It may be necessary to re-

tighten the pivot bolt after initial use as the plastic may still be conforming to the pressure from

the lock washers.

3. Adjust the height of the assembly so the face of the transducer is 1/8"

(3 mm) to 1/4" (6 mm) beneath the bottom of the transom, and fully

tighten the three mounting screws.

4. In order to gain access to the mounting screws, the transducer

assembly must be pivoted up in the bracket as shown. Be careful not

to alter the running angle as some force is necessary to pivot the

assembly.

5.

If access to the top mounting hole is not possible due to the selected height of the transducer,

fully tighten the two lower screws, then simply remove the headed pivot pin and the transducer

assembly, and tighten the top screw, then reassemble.

6. Confirm that the pivot angle has not changed and that all mounting screws are fully tightened.

Tighten the Mounting Screws

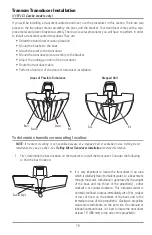

Normal Cavitation

Cavitation that will cause

erratic sonar readings

Screw

1

Headed Pin

2

Allen Wrench

3

Nylon Washer

4

Stainless Washer

5

3

1

5

4

2

22