UPS5000-S-300 kVA User Manual

(3P3W, 200 V)

8 Technical Specifications

Issue 01 (2020-03-06)

Copyright © Huawei Technologies Co., Ltd.

150

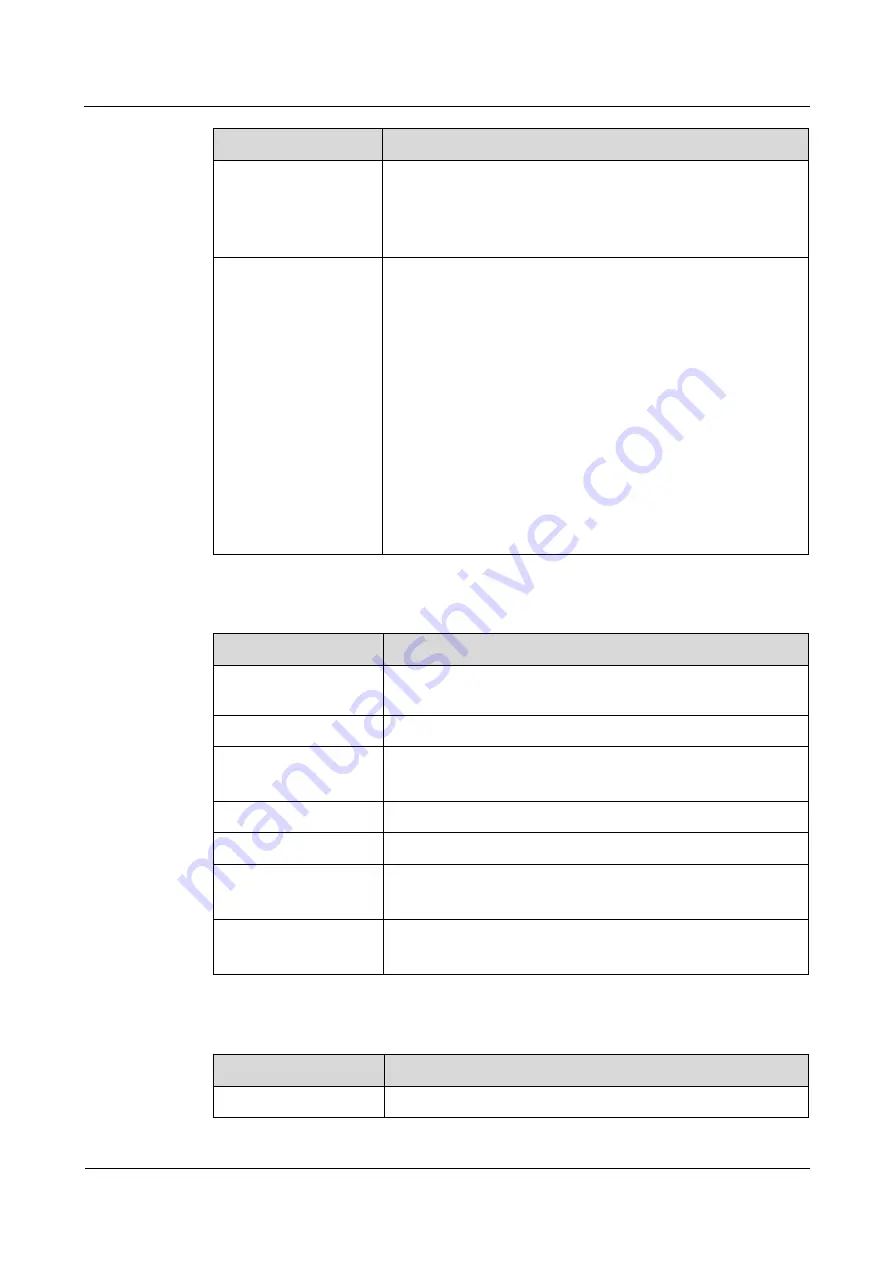

Item

Specifications

IEC62040-1: 2013

CQC3108-2011

YD/T1095-2000

GB/T4715-93

EMC

FCC Part15 Class A

EN62040-2

EN61000-4-3

EN61000-4-6

IEC62040-2

IEC61000-2-2

IEC61000-4-2

IEC61000-4-3

IEC61000-4-4

IEC61000-4-6

IEC61000-4-8

IEC61000-4-11

Table 8-4

Mains input electrical specifications

Item

Specifications

Input system

Three-phase, three-wire, and PE; does not support Δ-type

transformer input; supports only Y-type transformer input

Rated input voltage

200 V AC (line voltage)

Input voltage

160–240 V AC: not derated

138–160 V AC: derated

Rated frequency

50 Hz or 60 Hz

Input frequency

40–70 Hz

Input PF

> 0.99 (full load)

> 0.98 (half load)

THDi

THDi ≤ 3% (full linear load)

THDi ≤ 5% (full non-linear load)

Table 8-5

Bypass input electrical specifications

Item

Specifications

Input system

Three-phase, three-wire, and PE; does not support Δ-type