SmartACU2000B smart array controller

User Manual (with PID modules, 800 V AC)

5 Electrical Connections

Issue 05 (2019-01-20)

Copyright © Huawei Technologies Co., Ltd.

78

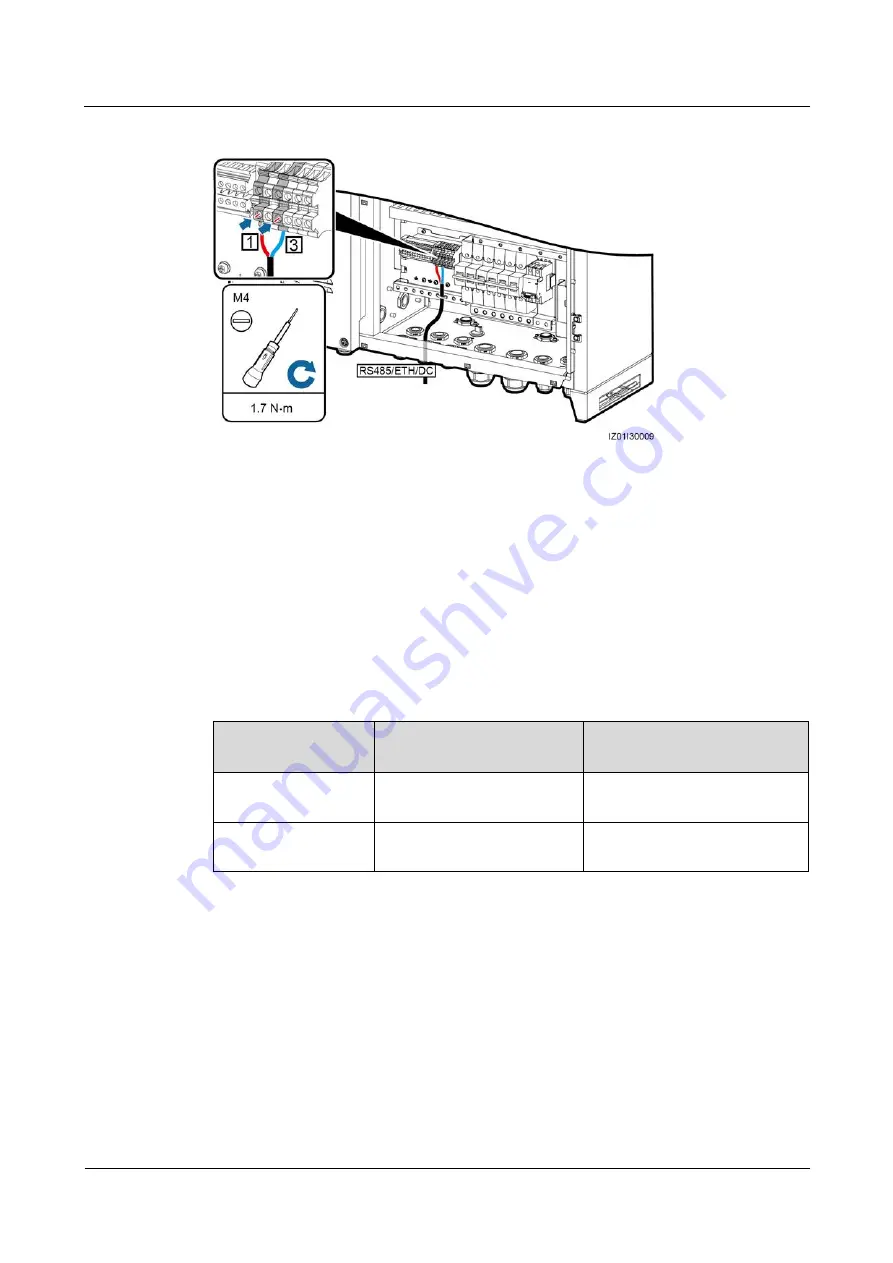

Figure 5-27

Connecting cables

----End

5.14 Connecting the 24 V DC Input Power Cable

Context

You can connect one 24 V DC input power cable to the smart array controller that supports 24

V DC input and output.

Table 5-3

Mapping

No.

Port on the JX02 Terminal

Block

Definition

5

24VIN+

Positive terminal of the 24 V DC

input power cable

6

24VIN–

Negative terminal of the 24 V

DC input power cable

Procedure

Step 1

Prepare cables.