ETP4830-A1 Embedded Power

User Manual

6 Commissioning

Issue 10 (2017-08-08)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

41

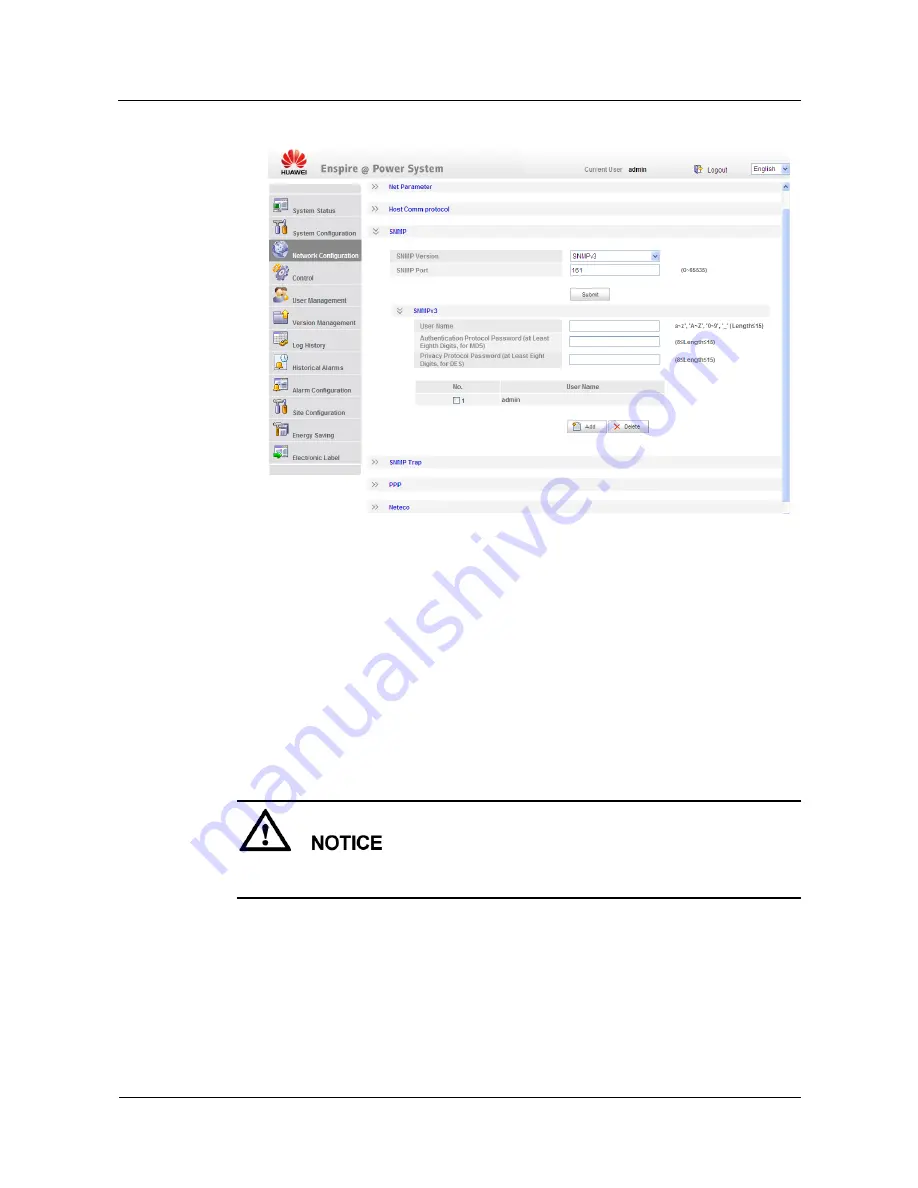

Figure 6-3

SNMPv3 parameters

Step 7

Set the SNMP trap destination address and trap port.

Step 8

Upload the MIB libraries

HUAWEI-MIB.mib

and

HUAWEI-SITE-MONITOR-MIB.mib

to the NMS.

----End

6.10 Connecting the Battery Supply

Prerequisites

To avoid damage to batteries, reinstall the battery fuse only after correctly setting the battery

parameters for the monitoring unit.

Procedure

Step 1

Switch off the AC circuit breaker for the upper-level device, and then reinstall the battery

fuse.

Step 2

Switch on the AC circuit breaker for the upper-level device, and then reinstall the load fuses.

Step 3

Check whether the battery voltage and system output voltage are the same as the voltages

displayed on the SMU LCD. If not, ask the technical support personnel to rectify the fault.