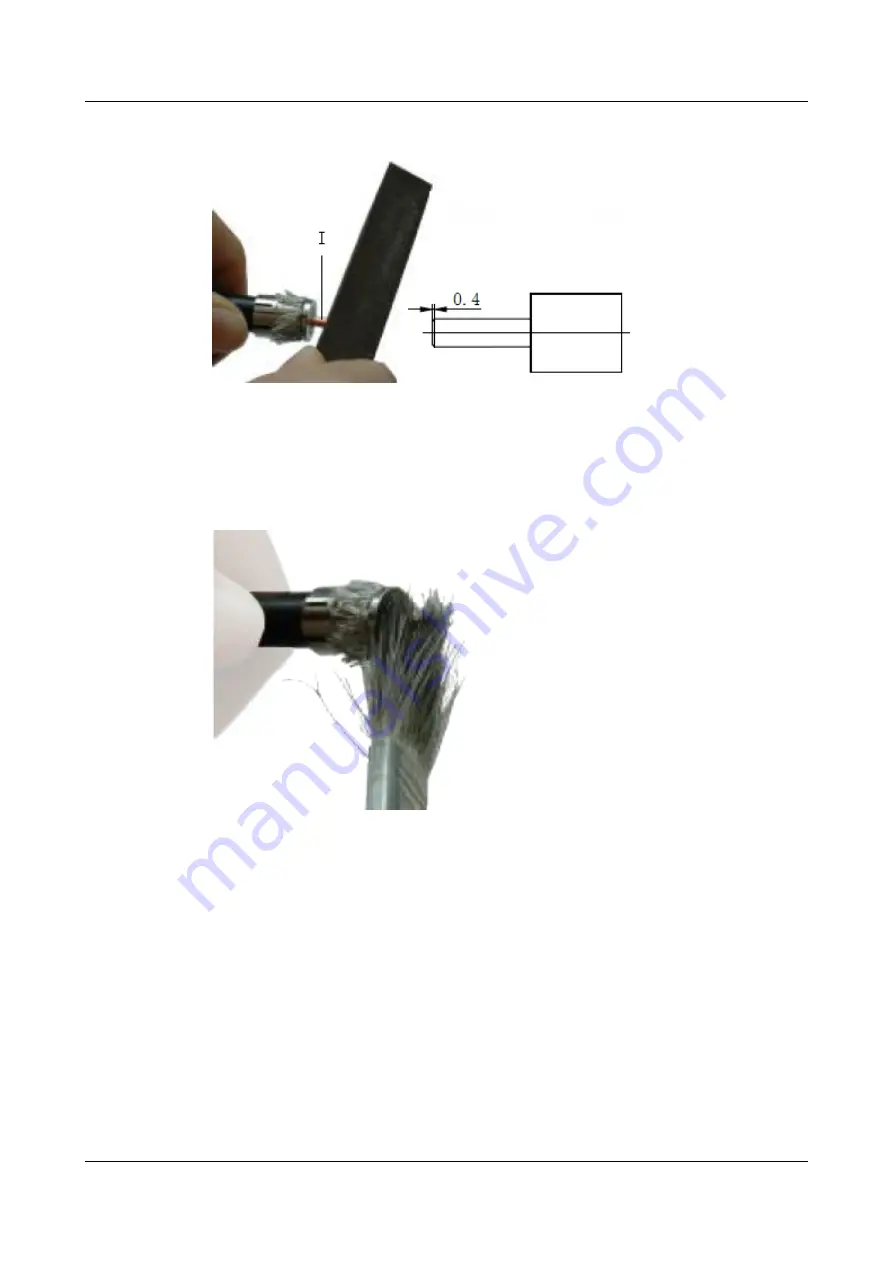

Figure 6-103

Tapering the internal conductor of the feeder

Step 8

Use a brush to remove impurities from the cross section of the feeder, as shown in

.

Figure 6-104

Clearing impurities

Step 9

Insert the half-finished part into the main body of the connector (A) and rotate the nut (D) and

the connector's main body until you cannot rotate further, as shown in

.

AP8082DN and AP8182DN

Hardware Installation and Maintenance Guide

6 Appendix

Issue 03 (2019-04-01)

Copyright © Huawei Technologies Co., Ltd.

107