-

24

-

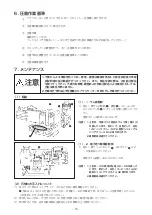

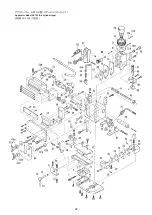

(3) 供料指的位置调整

1) 用六角扳手 (M4 用 ) 拧松供料指安装螺丝

1

。(

A

方向 )

2) 把供料指

2

对准传送器的操作孔的中心。

3) 用六角扳手拧紧供料指的安装螺丝

1

。(

B

方向 )

( 注意 ) 拧紧螺丝后,请再次确认供料指的位置。

(4) 废屑防护器安装位置的调整

1) 用六角扳手 (M4 用 ) 拧松废屑防护器安装螺丝

3

。(

A

方向 )

2) 调整高度,不让从切断钳出来的传送器

4

与废屑防护器

5

相碰。

然后,调整前后位置,不让夹杆

6

碰到废屑防护器

5

。

3) 用六角扳手拧紧废屑防护器安装螺丝

3

。(

B

方向 )

(3) Adjusting the position of the feed finger

1) Loosen feed finger mounting screw

1

using a hexagonal wrench key (for M4). (direction

A

).

2) Adjust feed finger

2

to the center of the pilot hole of the carrier.

3) Tighten feed finger mounting screw

1

with a hexagonal wrench key (direction

B

).

(Caution) After tightening the screw, check again the position of the feed finger.

(4) Adjusting the mounting position of the scrap guard

1) Loosen scrap guard mounting screw

3

using a hexagonal wrench key. (for M4) (direction

A

).

2) Adjust the height so that scrap guard

5

does not come in contact with carrier

4

coming out from the cut-off

punch.

Adjust the longitudinal position so that crimper

6

does not come in contact with scrap guard

5

.

3) Tighten scrap guard mounting screw

3

with a hexagonal wrench key (direction

B

).

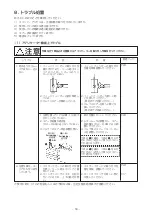

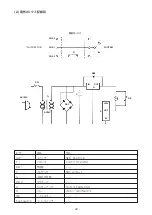

(5) How to adjust the position of the terminal

* If the rolling or twist is defective in shape, adjust the position of the terminal.

1) Detach the air supply from the regulator of the electrical box.

2) Loosen stopper bolt holder fixing bolt

8

with the terminal set in position. Then, detach stopper bolt holder

9

.

3) Loosen stopper bolt fixing nut

!0

.

4) If terminal

!1

is situated on the left of anvil

!2

, turn the stopper bolt in the direction of arrow

A

. If the terminal is

situated on the right, turn the stopper bolt in the direction of arrow

B

. Once the terminal is brought to just above

!4

the anvil, tighten fixing nut

!0

.

(5) 端子位置的调整方法

★ 如果压接和捻线形状不良的话,请调整端子位置。

1) 请从电气箱的调节器卸下空气源。

2) 在安装了端子的状态下,请拧松止动器螺栓支架固定螺栓

8

,然后卸下止动器螺栓支架

9

。

3) 请拧松止动器螺栓固定螺母

!0

。

4) 端子

!1

在砧台

!2

的左方时,向箭头

A

方向转动止动器螺栓,在右方时,向箭头

B

方向转动。端子移动到砧台

的上方

!4

之后,请拧紧固定螺母

!0

。