p

romo

• Before carrying out any maintenance on this sprayer, it is

essential to depressurise the bottle by activating the pressure

release valve.

• This sprayer is intended for use with water-based solutions of:

insecticides, fungicides, weedkillers & fertilizers.

• Always follow the chemical suppliers instructions, as well as

the instructions supplied with this sprayer.

Always wear protective clothing, goggles, face mask and

gloves.

Avoid inhaling spray mist.

Avoid skin contact with chemicals.

Always work in a well ventilated area.

Take care to protect children, pets & fish from exposure to

chemicals.

Always wash hands thoroughly after use & especially before

eating.

Always wash any contaminated clothing.

Seek medical attention if spray gets in your eyes or you

develop any symptoms after spraying.

Do not spray near food or food preparation areas.When

spraying crops, pay particular attention to the chemical

manufacturers advice on time before crops can be eaten.

Do not spray any solvent e.g. White spirit.

Spray only thin watery solutions; thicker mixtures will clog

the nozzle.

Powdered chemicals can be sprayed successfully if they are

completely soluble in water. If they are not, or the solution

tends to settle, spraying can still be successful if the mixture

is continually agitated.

If the material to be sprayed contains sediment, strain the

liquid into the sprayer bottle.

Do not over pressurise the bottle, or tamper with the

pressure release valve. The pressure release valve is designed

to release excess pressure do not interfere with it or force it

to remain closed.

Winter Use – drain liquid from all parts and prevent damage

from freezing.

Annual maintenance – At least once per year thoroughly

clean the whole sprayer and apply silicone grease to all

moving parts & seals. Test with water, and if any washer or

seal has perished it must be replaced.

• Before carry out any maintenance on this sprayer. It is essential

to depressurise the bottle by activating the pressure release

valve.

Make sure all nuts are screwed hand tight before use.

This sprayer is made from many different types of plastic,

and although the liquid you wish to spray may be packed in

plastic, this does not guarantee it will not damage the sprayer.

If you have any doubt about compatibility contact Hozelock

consumer services. When filling the sprayer ensure that the

maximum fill level is not exceeded.

Ensure that the pump is screwed into the bottle tightly.

Operate the pressure release valve manually to ensure it is

functioning correctly and able to move.

If the sprayer has been used with chemicals, discard safely any

unused solution after use.

Fill sprayer with warm water (not hot),

re-assemble the sprayer and spray some of the contents.

Repeat; check that the nozzle is free from sediment.

If necessary repeat the process until the sprayer is clean.

NB : Do not use detergent.

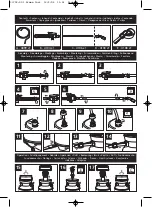

The pump O-ring should be lubricated to allow the sprayer to

pump air efficiently. Apply silicone grease regularly, to the

pump O Rings (A) and piston.

The nozzle cap (B) & swirl grooves (C) should be kept clean

and free of obstruction. The O-ring should be lubricated to

allow the spray pattern to be easily changed. Apply silicone

grease regularly, to the nozzle O Ring (D).

Keep the trigger clean and free from build up of sediment and

chemicals by regularly flushing after use. If necessary remove

and clean the shuttle in the trigger.

To clean or replace washers and O-ring in the dip tube.

Depressurise the bottle first, unscrew the hose nut and pull dip

tube assembly out.

• Hozelock guarantees this sprayer against any defect arising

from faulty materials or workmanship for a period of 2 years

from the date of purchase, provided that it has only been used

in accordance with these instructions. The guarantee is limited

to the repair or replacement of any defective or faulty item.

Proof of purchase must be retained.

• Hozelock extended guarantee, above, covers the bottle and

pump mechanism only. It specifically excludes: all O-rings &

seals, the hose, and the lance assembly. These have a 12-month

guarantee, are wearing parts and are available as spares from

the retailer or from Hozelock direct.

Hozelock Limited

Midpoint Park, Birmingham. B76 1AB

Tel : +44 (0) 121 313 1122

Internet : www.hozelock.com

Email : [email protected]

J

I

H

G

F

E

D

C

B

A

GB

Instructions & Warnings

Notes

Troubleshooting

Guarantee

Contact Details

Issue

Problem

Solution

Weak or

no spray

Sprayer will not

pressurise

Ensure all connections are tight

Check O rings and seals are

lubricated and show no signs of

wear or damage – replace if

required (see notes G, I & J)

Obstruction

There could be a blockage in the

nozzle, or the trigger or the

outlet tube

Distorted

Spray

Obstruction

There could be a blockage in the

nozzle

Leaks

Build up of

sediment or

foreign matter on

sealing surfaces

Check O rings and seals are free

from dirt – Clean or replace if

required

Worn or

damaged O rings

/ Washers

Check O rings and seals are free

from wear or damage – replace

if required

Handle

rises

Faulty non return

valve (X)

This stops the compressed air in

the container from escaping

back into the pump

If faulty the unlocked pump

handle will rise when the

container is pressurised. To

remove the valve, lift the edge

and pull (NB take care not to

damage the sealing face of the

barrel. Replace with a new valve

by pushing firmly over the

centre hole

33798-001 Promo Inst 12/2/08 11:51 Page 4