Sensepoint XCD Technical Manual SPXCDHMANEN Issue 2

63

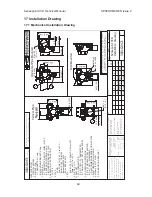

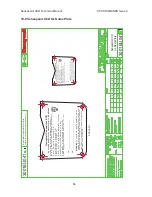

18.5 Sensepoint XCD ATEX Name Plate

Sensepoint XCD ATEX Name Plate

NONE

A

16/MAY/08

NEW

DRA

WING

J.Y

.JIN

H

on

ey

w

el

l S

en

se

po

in

t XCD

H

on

ey

w

el

l A

na

ly

ti

cs

In

c.

L

in

co

ln

sh

ir

e,

IL

, U

S

A

6

00

69

R

ea

d

S

en

se

po

in

t X

C

D

M

an

ua

l p

rio

r

to

u

se

a

nd

in

st

al

l a

s

pe

r

C

on

tr

ol

D

ra

w

in

g

N

o.

30

01

E

A

04

1.

T

em

p.

C

od

e

T4

3

2V

ol

ts

D

C

M

A

X

. C

la

ss

2

, P

m

ax

=5

W

II

2

G

D

E

x

d

IIC

G

b

T6

(T

a

-4

0

℃

to +65

℃)

E

x

tb

II

IC

T

85

℃

D

b

IP

66

B

as

ee

fa

08

A

TE

X

02

22

IE

C

E

x

B

A

S

0

8.

0072

03

44

W

A

R

N

IN

G

:

D

O

N

O

T

O

P

E

N

W

H

E

N

E

N

E

R

G

IS

E

D

O

R

W

H

E

N

A

N

E

X

P

LO

S

IV

E

G

A

S

A

TM

O

S

P

H

E

R

E

IS

P

R

E

S

E

N

T

B

17/JUN/08

MARKING REVISED

J.Y

.JIN

JIS G4304: SUS 316 Minimum Thickness: 0.5mm

S

/N

:

P

/N

:

C

14/JUL/08

CHANGED NOTES

J.Y

.JIN

D

08

/SEP/08

CHANGED NOTES

J.Y

.JIN

E

16

/SEP/08

ADD Certi. Numbers

J.Y

.JIN

NOTES 1. This is an ATEX schedule drawing and can only be changed after approval is given by the certifiying body 2. Serial no. format S/N: SIIPPPYYWWNNN

Sequence number Week of MFG Year of MFG Part Code Issue State SUPPLIER CODE 3. Etching Depth : 0.1 mm

THIS DOCUMENT

HAS BEEN GENERA

TED USDING

ADOBE ILLUSTRATOR AND MUST ONLY BE UPDATED BY A.I.

3001EA041

3001EA041

BEN HUR

16

MAY 08

NONE

THIS

DRA

WING

IS

CONFIDEN

-

TIAL.

IT

IS

THE

PROPER

TY

OF

HONEYWELL

ANAL

YTICS

LTD

AND

MUST

NOT

BE

REPRO

-

DUCED

EITHER

WHOOL

Y

OR

PAR

TL

Y.

ALL

RIGHTS

IN

RESPECT

OF

PA

TENTS,

DESIGNS

AND

COPYRIGHT

ARE RESER

VED.

APPROVED

BY

CHANGE

DA

TE

ISSUE

SCALE

MA

TERIAL

FINISH

TITILE

DRA

WING

SHT

.

OF

THIS ITEM FORMS P

AR

T OF

A CER

TIFIED PRODUCT

NO MODIFICA

TION PERMITTED WITHOUT

REFERENCE

TO CER

TIFICA

TION DEP

AR

TMENT

SHT

.

1

30

/SEP/08

ADD Certi. IP66

J.Y

.JIN

Summary of Contents for Sensepoint XCD

Page 1: ...Technical Manual Sensepoint XCD Gas Detector P R E L A U N C H ...

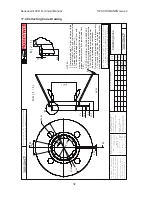

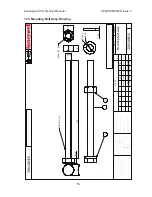

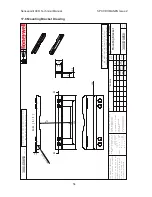

Page 54: ...Sensepoint XCD Technical Manual SPXCDHMANEN Issue 2 54 17 6 Mounting Bracket Drawing ...

Page 56: ...Sensepoint XCD Technical Manual SPXCDHMANEN Issue 2 56 China GB Ex English Version ...

Page 57: ...Sensepoint XCD Technical Manual SPXCDHMANEN Issue 2 57 China PA Certification ...

Page 58: ...Sensepoint XCD Technical Manual SPXCDHMANEN Issue 2 58 18 2 Korea KTL ...

Page 60: ...Sensepoint XCD Technical Manual SPXCDHMANEN Issue 2 60 ATEX for Sensor ...

Page 62: ...Sensepoint XCD Technical Manual SPXCDHMANEN Issue 2 62 IEC Ex for Sensor ...