25

MM06UE01-2002

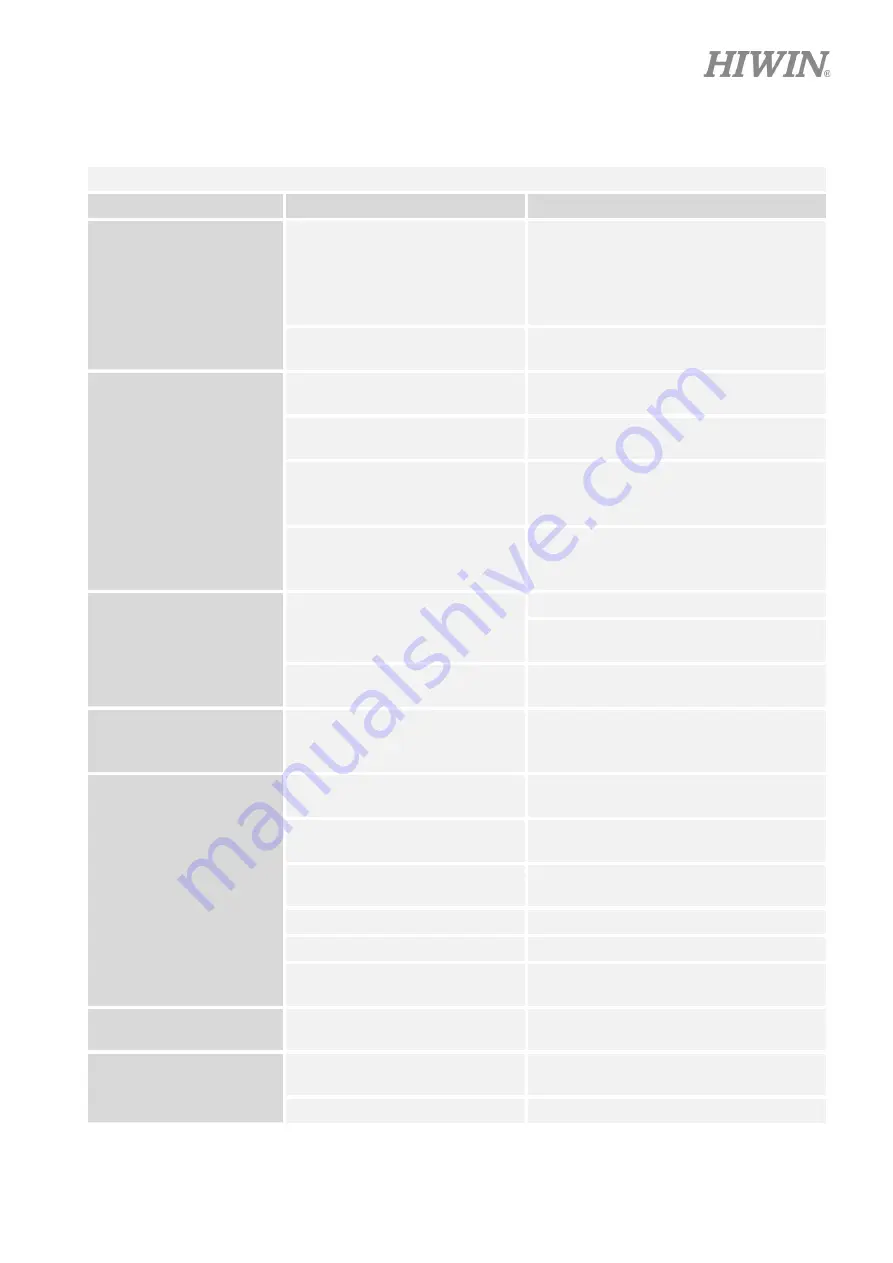

8. Troubleshooting

Table 8.1

Fault table

Fault

Possible cause

Remedy

Motor does not start

Supply lines disconnected

Check connections, plug contacts may be

compressed, repair if necessary.

The connectors have seals, which means

that a certain screw connection resistance

must be overcome.

Fuse has tripped via motor

protection

Check motor protection for the right settings,

remedy defects if necessary

Upon restart, the drive

reports a fault during

commutation

Motor phases connected

incorrectly

Check rotational direction

Encoder counting direction

incorrect

Change the sin and cos pair of wires in the

encoder plug

forcer housing is too close to the

limit switch/limit stop

Disconnect power supply to axis and move

forcer housing manually into the center of

the axis.

Additional drive resistance e.g.

sealing lip, without parameter

adjustment

Change parameters in the drive amplifier

Axis overspeeds upon

restart

Commutation incorrect

See fault during commutation

Check commutation parameters in the drive,

activate speed monitoring!

EMC interference with the encoder

signal

Check the shielding of the connectors and

cables

Axis overspeeds in

positioning mode

Programming error in the position

transfer, invalid acceleration

ordered

Activate security settings in the drive

amplifier, such as speed monitoring,

permissible position errors etc.

Motor heats up too much

(measure temperature)

Rated power exceeded as duty

cycle is too long

Adapt load cycle to the rated power of the

motor

Cooling insufficient

Rectify cooling air supply or open cooling air

passages, retrofit external fan if necessary

forcer housing is difficult to move

Check lubrication of the guideways, foreign

bodies in the traversing range?

Ambient temperature too high

Observe permissible temperature range

Load cycle has been modified

Calculate load cycle and adapt accordingly

Drive amplifier motor commutation

does not function properly

Adapt commutation parameters of the drive

amplifier

Operating noise from the

forcer

Relubrication required otherwise

risk of bearing damage

Lubrication or consultation with HIWIN

MIKROSYSTEM

The axis generates cracking

noises when it is subject to

control

EMC interference in the encoder

signal

Encoder cables must be used separately

with shielded sin and cos signal pairs

Commutation incorrect

Optimize commutation parameters.