Maintenance and Inspection (continued)

22

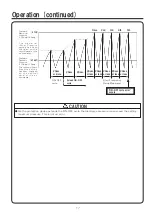

Component

Inspection

Instructions

Maintenance and Inspection Time Interval

Remarks

Daily

Every

500 Hours

or 2 Months

Every

2,500 Hours

or 1 Year

Every

5,000 Hours

or 2 Years

Every

10,000Hours

or 4 Years

Every

20,000Hours

or 8 Years

Air Receiver Tank

(Option)

Drain accumulated

condensate in air receiver.

○

Accumlation of dirt of

dust

Check or clean.

○

Complete Air

Compressor

Inspect for excessive

noise and vibration.

○

Refer to page 25.

Safety Relief Valve

Inspect operation.

○

Replace the safety relief

valve if there is any

damage.

Pressure Sensor

Inspect operation and

pressure display confirm.

○

Replace the sensor if

there is any damage.

Check Valve

Inspect for leaks or

replace.

○

●

Ventilating Fan

Inspect or replace

the ventilating fan.

○

●

Refer to page 26.

Bolts, Nuts & Screws

Inspect and tighten any

loose items.

○

Refer to page 26.

Intake Air Filter

Replace a dirty or

clogged filter.

○

●

◎

Refer to page 26.

Sirocco Fan & Scroll

Fin

Clean the dirt off

these components.

○

◎

Scroll Bearing

Grease or inspect

the bearing.

○

◎

Replace the scroll head if

there is any damage with

bearing.

Tip Seal & Face Seal

Replace the seals.

●

◎

Bearings

Inspect the bearings.

○

◎

Replace the scroll head if

there is any damage with

bearings.

Scroll Head

Replace the scroll

head.

●

Rubber Hose

Inspect for leaks.

○

●

R e p l a c e t h e r u b b e r

h o s e i f t h e r e i s a n y

damage.

V-Belts

I n s p e c t , a d j u s t a n d / o r

replace a loose or damage

v-belt

○

●

Refer to page 27.

Electromagnetic

Contactor

Inspect or replace.

○

●

Rubber Vibration

Isolator Pads

Inspect for any damage

and/or hardness.

○

R e p l a c e t h e p a d s i f

there is any damage.

Electric Main Motor

Inspect for any damage.

○

Replace the motor if

there is any damage.

Coolers

Clean the dirt off or

replace.

○

●

【145PSIG Model】

※ ○ represents the periodic inspection period during operation or after parts have been replaced and a ● represents the

parts replacement period.

※ ◎ represents parts that should be replaced at the same time as the scroll head replacement.

※ Operation time on the control panel digital display is the total running hours of the SRL air compressor.

※ The maintenance and service time intervals shown are for normal operation. The inspection period may differ slightly

for different operating conditions, such as high temperature and/or humidity. If the operating conditions are severe and/or

unsatisfactory, reduce the inspection time intervals.

※ Carry out the maintenance and inspections based on the recommended total operating hours and/or calendar time in the

maintenance schedule, whichever occurs first.

※ It is recommended to request maintenance and inspection from the local Hitachi distributor for any items in the shaded

area ( ).