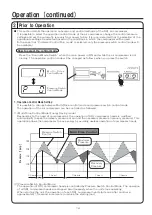

■ Cycle Control Logic (CCL): Operation and protection from excessive cycling of the main motors

● The SRL air compressor measures the "ON-OFF cycle number" after the pressure settings have been

changed and automatically adjusts the maximum (stop) pressure to prevent the "ON-OFF cycle" from

increasing when the "ON-OFF cycle number" increases exponentially, thus protecting the scroll head,

electric motor and electromagnetic contactor (Please see the figure below).

● After the CCL adjusts the maximum (stop) pressure, the CCL continues to automatically measure the

"ON-OFF cycle number" and lower the maximum (stop) pressure within the permissible range of the

"ON-OFF cycle number", until the CCL nears the set maximum (stop) pressure of the air compressor

and the "ON-OFF cycle number" becomes consistent.

● A protection device is equipped on this unit to prevent frequent ON-OFF operations. Start Frequency

Protection automatically measures cycles of ON-OFF, and in the case that the cycle of ON-OFF is less

than 20 seconds, the operation will continued for 20 seconds even if the maximum pressure setting is

lowered. In the event that it takes less than 20 seconds to reach the standard maximum pressure

(122psig/145psig) the controller will stop the operation of the air compressor at 122psig/145psig.

If this happens 5 times continuously, it is defined as a「ON-OFF cycle error」. If this occurs「E.CY」

will be indicated on the digital display, and the operation of the air compressor will stop to protect the

compressor head, electric motors and electromagnetic contactor.

● Pressing the Stop switch will reset the unit from the「ON-OFF cycle error」, and allow it to restart the

operation of the air compressor. However, if the situation which caused the「ON-OFF cycle error」

is

not eliminated, the「ON-OFF cycle error」

will occur again.

● To lower the amount of cycles of ON-OFF the recovery pressure will need to be lowered by following

the procedure for changing the control pressure setting. (Refer to P.15)

If the recovery pressure is already set at its lowest point, a larger air receiver will need to be installed.

16

Operation (continued)

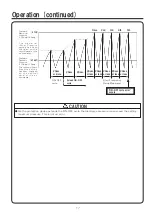

■ Changeable Pressure Ranges

122 PSIG Model

Pressure

Description

Maximum (Stop)

Pressure (psig)

Recovery (Start)

Pressure (psig)

Pressure

Bandwidth (psig)

Pressure Unit

Interval of Change

Standard Pressure

122

110

12

-

Changeable

Pressure Range

122 - 92

110 - 80

12

1

145 PSIG Model

Pressure

Description

Maximum (Stop)

Pressure (psig)

Recovery (Start)

Pressure (psig)

Pressure

Bandwidth (psig)

Pressure Unit

Interval of Change

Standard Pressure

145

115

30

-

Changeable

Pressure Range

145 - 95

130 - 80

15

1

Notes: 1. When operating the air compressor with a pressure bandwidth of 30 psig it is recommended that a large size vertical air receiver

is installed.

2. The pressure bandwidth of the maximum pressure and the recovery pressure cannot be lower than 12/15psig. The interval of

pressure change is 1psig.

3. The air compressor may keep running over the maximum pressure of 122psig/145psig because of the Start Frequency

Protection even if the maximum pressure is lowered.