10.3.2 Wire size and Main switch protection

Recommended minimum sizes for field provided wires and select the main switches according to the next table:

Model

Power supply

Power source cable size

Transmitting cable size

MC

(A)

CB

(A)

ElB

(nº poles/A/mA)

EN60 335-1

EN60 335-1

RAS-2WHVRP

1~ 230V 50Hz

2.5 mm

2

0.75 mm

2

13

16

2/40/30

RAS-2.5WHVRP

2.5 mm

2

13

16

RAS-3WHVRP

4.0 mm

2

17

20

?

N O T E

• ELB: Earth switch; CB: Circuit breaker

• Follow local codes and regulations when selecting field wires, Circuit breakers and Earth Leakage breakers.

• Use the wires which are not lighter than the ordinary polychloroprene sheathed flexible cord (code designation 60245 IEC 57).

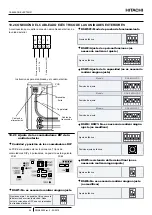

11 COMMISSIONINg

When installation is completed, perform test run according to the

Indoor Unit Installation and Operation Manual, and hand over

the system to the customer.

?

C A U T I O N

Do not operate the system until all the check points have been cleared:

• Check to ensure that the electrical resistance is more than 1 MΩ, by

measuring the resistance between ground and the terminal of the

electrical parts. If not, do not operate the system until the electrical

leakage is found and repaired. Do not impress the voltage on the

terminals for transmission 1 and 2.

•

Check to ensure that the stop valves of the outdoor unit are fully

opened, and then start the system.

•

Check to ensure that the switch on the main power source has been

ON for more than 12 hours, to warm the compressor oil by the oil

heater.

•

Pay attention to the following items while the system is running:

•

Do not touch any of the parts by hand at the discharge gas side,

since the compressor chamber and the pipes at the discharge side

are heated higher than 90°C.

• DO NOT PUSH THE BUTTON OF THE MAGNETIC SWITCH(ES), it

will cause a serious accident.

•

Do not touch any electrical components for more than three minutes

after turning OFF the main switch.

• Confirm that the gas line stop valve and the liquid line stop valve are

fully open.

• Confirm that the leakage of the refrigerant does not exist. The flare

nuts are sometimes loosened by vibration during transportation.

•

Check that the refrigerant piping and the electrical wiring conform to

the same system.

• Confirm that the dip switch setting on the printed circuit board of the

indoor units and the outdoor units are correct.

•

Check whether or not the electrical wiring of the indoor units and the

outdoor units are connected properly.

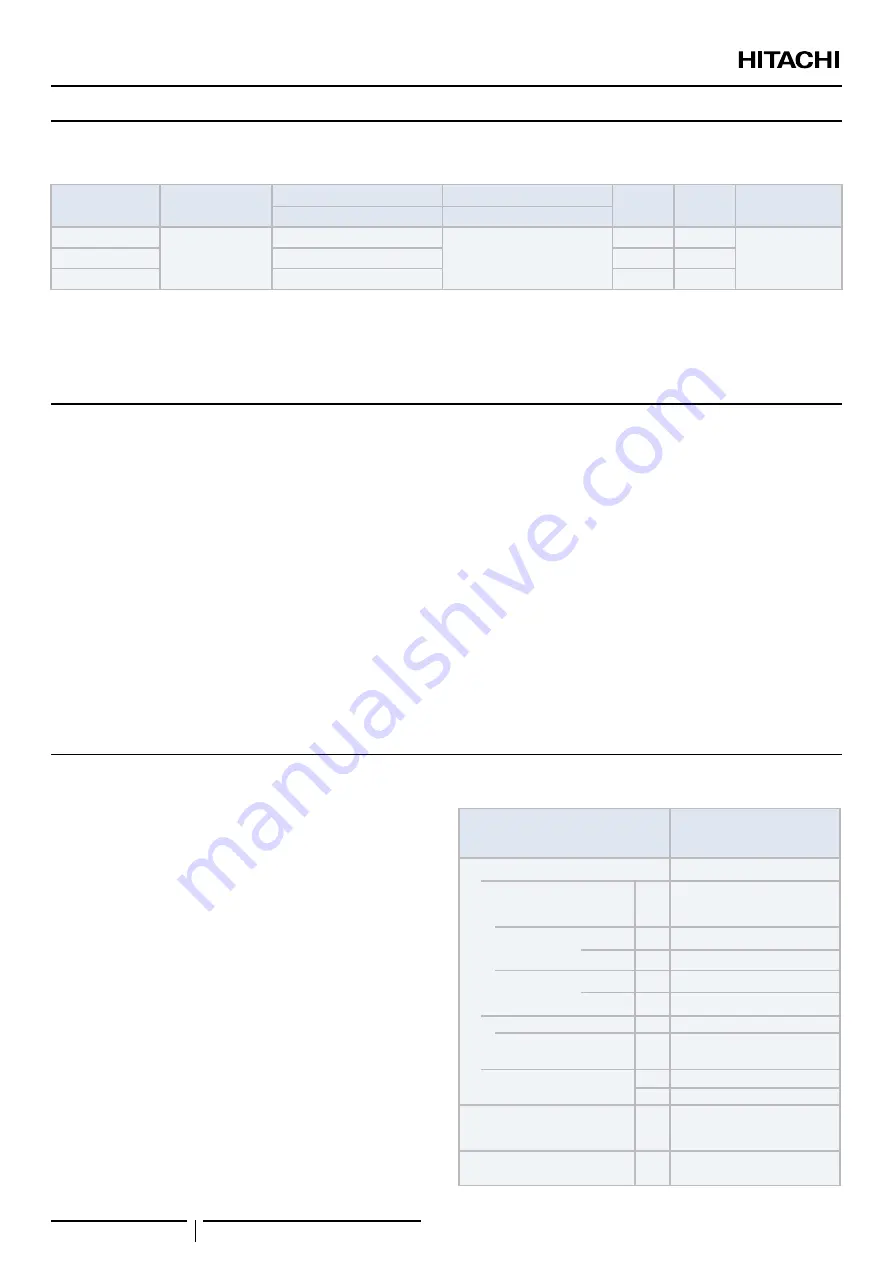

12 MAIN SAFETY DEvICES

Compressor Protection

High pressure switch:

This switch cuts out the operation of the compressor when the

discharge pressure exceeds the setting.

Fan Motor Protection

When the fan motor current is reached to the setting, motor

output is decreased.

The other way, when the fan motor current becomes lower,

limitation is cancelled.

Model

RAS-2whvRP

RAS-2.5whvRP

RAS-3whvRP

For Compressor

Pressure Switches

-

Automatic Reset, Non-

Adjustable (each one for each

compressor)

High

Cut-Out MPa

4.15

Cut-In

MPa

3.20

Low

Cut-Out MPa

0.30

for control

Cut-In

MPa

0.20

Fuse

-

1~ 230V 50Hz

A

40

CCP Timer

-

Non-Adjustable

Setting Time

min.

3

For Condenser Fan Motor

-

Automatic Reset, Non-

Adjustable (each one for each

motor)

Internal Thermostat

For Control Circuit

A

5

Fuse on PCB

COMMISSIONING

PMML0509 rev.0 - 02/2019

14