-1-

Equipped with four existing electronic co two most

advanced controls

These products are highly functional electronic disc grinders that provide added value and incorporate a

microcomputer with a new original program loaded in place of a conventional general-purpose IC, four fully

updated control features—(1) constant speed control, (2) soft-start speed control, (3) variable speed control

(on Models G 12VA, G 13VA and G 15VA), and (4) overload protection control—and two new additional

control features—(5) kickback protection control and (6) 0-voltage restart protection control.

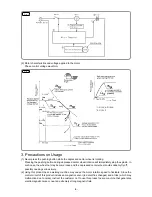

1. Constant speed control

The constant speed control feature maintains constant rotation speed during operation to ensure highly

efficient work.

2. Soft-start speed control

The soft-start speed control feature reduces the reactive force generated at motor startup so as to lessen

the load on the operator's hands.

3. Variable speed control (G 12VA, G 13VA and G 15VA only)

The variable speed control feature selects an appropriate rotation speed for different applications to

ensure highly efficient work.

4. Overload protection control

The overload protection feature shuts off power to the motor in the event of motor overload or a

conspicuous reduction in rotation speed during operation. This feature thus reduces the risk of motor

burnout and controller failure.

5. Kickback protection control

The kickback protection feature cuts off power to the motor and stops the power tool in the event of a

sudden drop in wheel rotation speed during operation (e.g., wheel locking during cutting operation). This

feature thus lessens the load on the operator's hands.

6. 0-voltage restart protection control

The 0-voltage restart protection feature disables motor startup even with the main switch on when the

power cord is reconnected to the power outlet after being unplugged during operation or when the power

supply is recovered from power failure. This feature thus minimizes accidents due to motor restart.

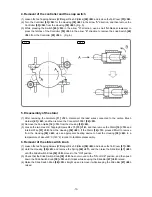

Equipped with most powerful motor in its class

These products are equipped with a high-performance, powerful motor featuring the highest input and

output in its class to enable highly efficient work.

Maker

HITACHI

Model

G 12VA, G 13VA, G 13YF,

G 15VA and G 15YF

B1, B2

C1, C2, C3

Power input

1500W

1400W

1400W

Max power output

2800W

2100W

2650W

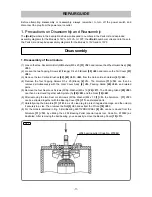

Excellent overload durability (G 13VA)

The Model G 13VA provides the highest overload durability in its class (1.2 times higher than that of B1)

thanks to an improved cooling mechanism and a high-power motor.

116

100

123

0

50

100

150

SELLING POINT DESCRIPTIONS

G 13VA

B1

C2

Practical test data: Comparison of torque at 200-K rise in stator coil temperature