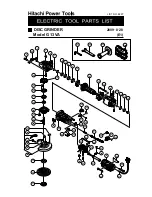

-14-

Perform reassembly by reversing the order of the disassembly procedure. However, special attention

should be given to the following items.

(1) Generously lubricate the teeth of the Gear and Pinion set

[19] <20>

with grease. Rub grease onto the

teeth with your fingers so that it reaches the bottom of each tooth. Note that insufficient lubrication may

result in faster wear of the Gear and Pinion set

[19] <20>

.

(2) Be sure to soak the inner diameter of the Felt Packing

[24] <25>

with machine oil. Otherwise, its dust-

sealing function will fail to work properly, resulting in premature damage to Ball Bearing 6201DDCMP2L

[23] <24>

.

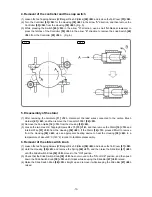

(3) When replacing the Armature

[11] <12>

or Ball Bearing 608VVC2PS2L

[17] <18>

on the commutator

side, be sure to replace Dust Seal (A)

[16] <17>

with a new one together. Dust Seal (A)

[16] <17>

is an

important part to ensure the dust resistance of the ball bearing. Replace Dust Seal (A)

[16] <17>

with a

new one without fail. Press-fit Ball Bearing 608VVC2PS2L

[17] <18>

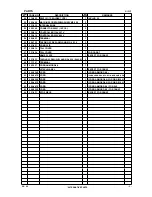

into the position shown in Fig. 7.

(4) Apply Three Bond TB 1406 Screw Locking Agent to the following screws:

• Two Seal Lock Screws (W/Sp. Washer) M4 x 10

[1] <3>

that secure the Bearing Cover

[10] <11>

in

place.

• Three Seal Lock Screws (W/Sp. Washer) M4 x 8

[21] <22>

that secure the Bearing Cover (B)

[22]

<23>

in place.

• Four Seal Lock Screws (W/Sp. Washer) M5 x 16

[26] <27>

that secure the Packing Gland

[25] <26>

in place.

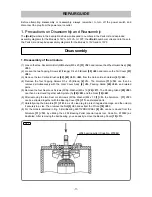

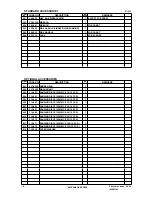

(5) Check that the end of the spring does not hold the pigtail when mounting the carbon brush. Do not catch

the pigtail in the tail cover when mounting the cover as shown in Fig. 8 below.

(6) When replacing the Gear Cover Ass'y

[4] <5>

, lubricate the needle bearing with mixed oil.

Mixed oil: Mixture of Hitachi power tool grease No. 2 (Unilube No. 00) and turbine oil

• Mixed ratio

-------

1:1 (weight ratio)

• Volume

----------

0.5 cc

Reassembly

Fig. 7

Press-fitting position:

4.2 to 4.5 mm

Thrust Washer

[15] <16>

Dust Seal (A)

[16] <17>

Ball Bearing

608VVC2PS2L

[17] <18>

Armature shaft

Magnet

[18] <19>

Fig. 8