Operating Procedures 7

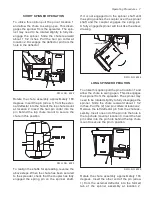

SHORT SPINNER OPERATION

To utilize this option pull the pin at location 1

and allow the chute to swing open. This disen-

gages the spinner from the spreader. The spin-

ner may need to be rotated slightly to fully dis-

engage the spinner. Slide the chute rearward

about 1 1/2 inches. Pull the hair pin cotter at

location 2. Disengage the deflector pin from the

hole in the deflector

DWG. NO. 6022

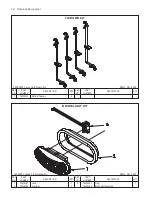

Rotate the chute assembly approximately 180

degrees. Insert the pin (arrow 1) from the exter-

nal deflector into the hole of the top chute mount

at location 2. Insert the hair pin cotter into the

pin behind the top chute mount to secure the

chute in this position.

DWG. NO. 6023

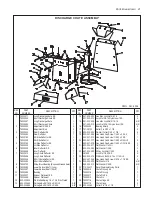

To realign the shafts for spreading, reverse the

above steps. When the chute has been secured

to the spreader, check that the coupler has fully

engaged the spring pin on the spinner shaft.

If it is not engaged turn the spinner shaft until

the spring pushes the coupler over the spinner

shaft and the coupler engages the spring pin.

A fully engaged spinner will look like the above

drawing.

SLIDE REARWARD

2

3

1

DWG. NO. 6024

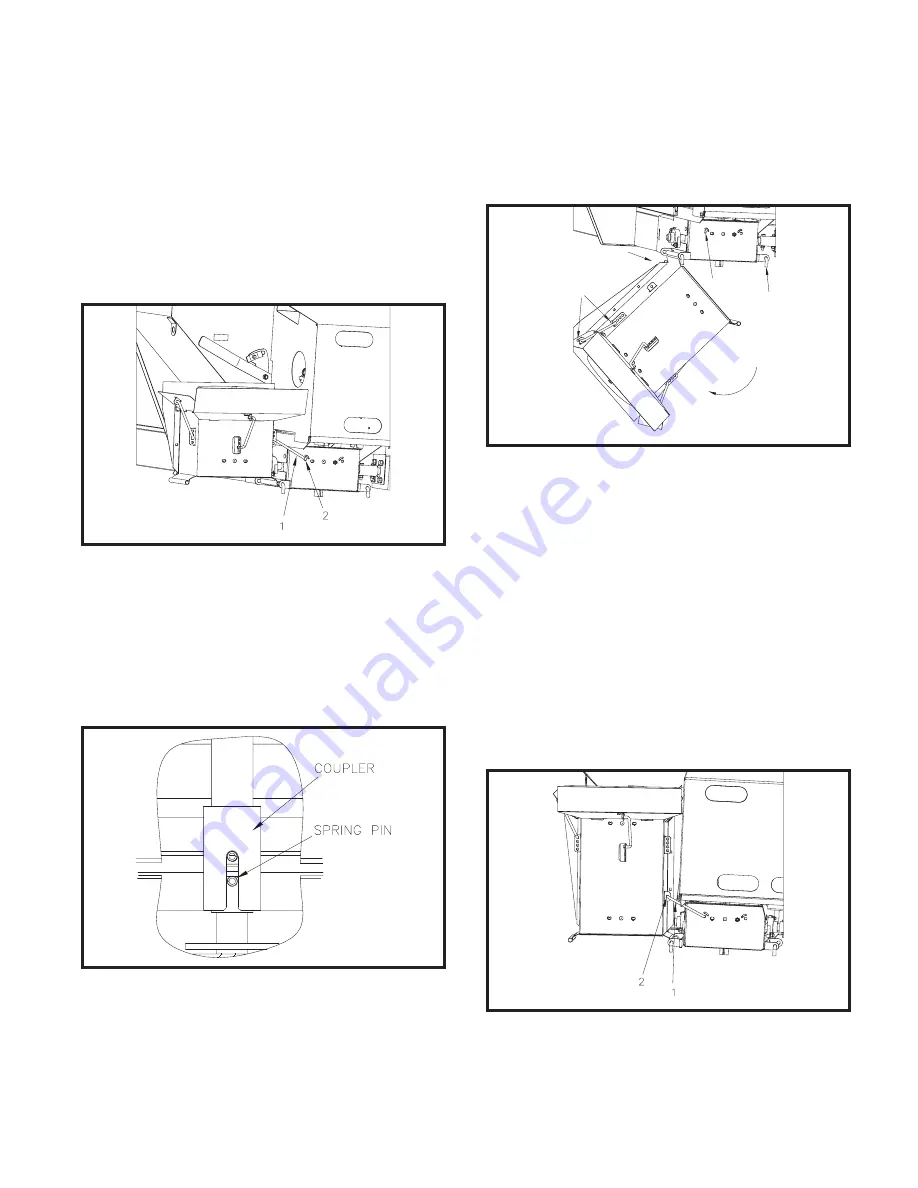

LONG SPINNER OPERATION

To utilize this option pull the pin at location 1 and

allow the chute to swing open. This disengages

the spinner from the spreader. The spinner may

need to be rotated slightly to fully disengage the

spinner. Slide the chute rearward about 1 1/2

inches. Pull the (2) hair pin cotters at location 2.

Remove the left deflector pin from the chute as-

sembly. Insert one end of the pin into the hole in

the top chute mount at location 3. Insert the hair

pin cotter into the pin hole behind the top chute

mount to secure the pin in position.

DWG. NO. 6025

Rotate the chute assembly approximately 180

degrees. Insert the other end of the pin (arrow

1) from the external deflector into the formed

tab of the spinner assembly at location 2.