10 Maintenance & Service Procedures

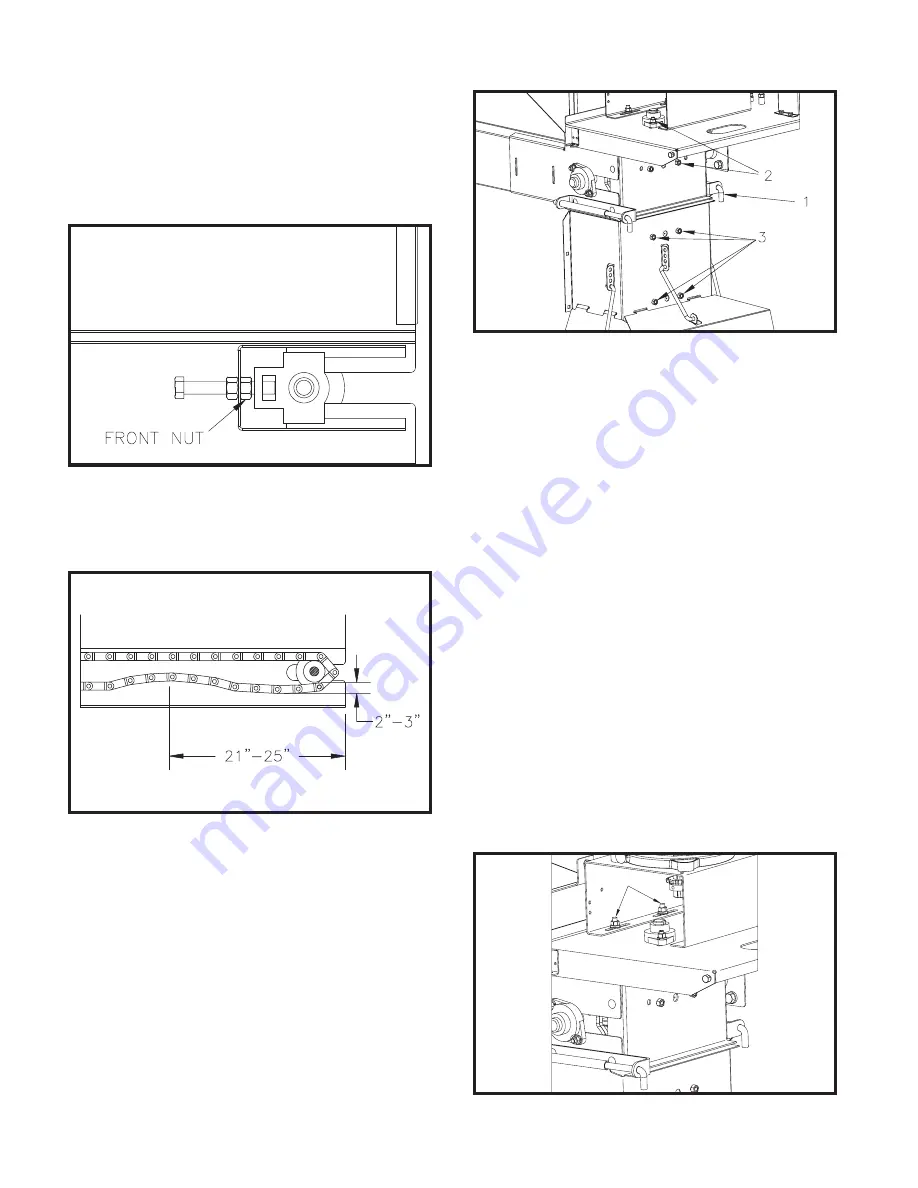

CHAIN TENSION

Tighten the conveyor chain periodically to com-

pensate for the chain stretching. Adjust both

sides the same amount to equalize the load on

the chain.

DWG. NO. 6026

Loosen the front nut, then turn the adjustment

bolt to take up the slack.

DWG. NO. 6596

Retighten the front nut after the chain is adjust-

ed. A properly tensioned chain can be pulled up

2-3 inches about 24 inches from the back of the

spreader side rails. A chain that is too tight will

cause excess stress on drive components.

DWG. NO. 6027

To adjust tension in the roller chain between the

gearbox and the spinner shaft first pull the pin at

location 1 and allow the spinner to swing open.

Loosen the (4) nuts, at location 2, that secure

the upper bearings which hold the upper spin-

ner shaft. Slide the top spinner shaft away from

the gearbox to tighten the chain. Make sure the

shaft is vertical before retightening the hard-

ware.

Rotate the chute assembly and reinsert the pin

at location 1. Loosen the (4) nuts, at location 3,

that secure the bearings which hold the bottom

spinner shaft. Slide the bottom shaft until it is

aligned with the top shaft.

When the shafts are aligned, the coupler on the

upper shaft will slide over the bottom shaft and

the spring pin will engage the slot in the cou-

pler. The bottom shaft may need to be rotated

slightly to align the slot in the coupler with the

spring pin. Make sure the bottom shaft is verti-

cal before retightening all hardware.

1

DWG. NO. 6028