Maintenance & Service Procedures 11

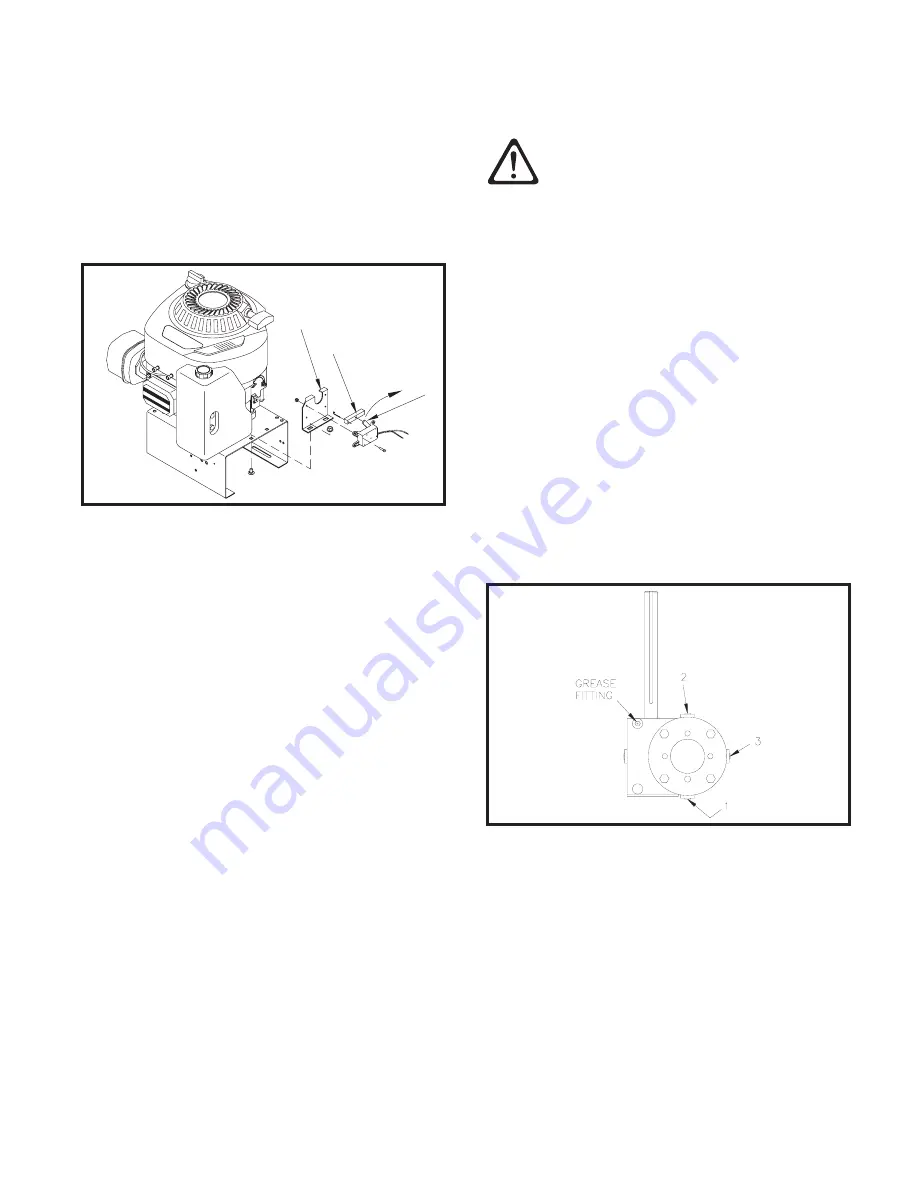

Tighten the engine drive chain by loosening the

four nuts (arrow 1)holding the engine plate, then

slide the entire engine assembly. Retighten nuts

to secure the engine plate

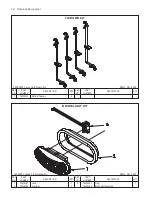

THROTTLE CONTROL ACTUATOR

Reassemble the throttle actuator as follows:

FORWARD

1

2

3

DWG. NO. 6040

1. Assemble the actuator on the bracket.

2. Advance the actuator arm (arrow 1) forward

with a 9V battery until the arm is stopped

by the bracket.

3. Place the plastic block (arrow 2) on the ac-

tuator arm and loosely bolt the bracket (ar-

row 3) on the engine plate.

4. Slide the governor control rack on the en-

gine fully ahead, then pin to the plastic

block.

5. Fully tighten the bracket to the engine

plate.

6. Cycle the actuator to verify that the arm is

stopped by the bracket, not by the engine

mechanism.

LUBRICATION

CAUTION: Do not lubricate, adjust or

clean the machine while it is running.

Death or serious injury can result.

Prior to operation of a new machine, or one that

has been stored, grease all bearing points with

a high quality SAE multi-purpose grease and oil

the roller chains.

Throughout the season, grease bearings at

about 10 hour intervals and oil roller chains of-

ten.

NOTE: Over-greasing may cause seal damage

to bearings. Use only one pump of grease per

fitting.

Replace gear box oil annually with SAE 90 gear

lubricant. Prevent debris from entering the gear

box by cleaning dirt from plug area and wiping

plugs prior to reinstallation.

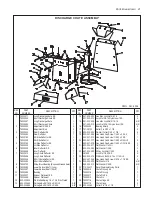

DWG. NO. 6031

Remove the drain plug at location 1 to drain old

oil into a quart or larger container and discard.

Reinstall the drain plug and remove the breath-

er at location 2 and the oil level plug at location

3. Fill the gearbox through the breather port un-

til oil appears at the level port. Reinstall the oil

level plug, add another 1/4 quart then reinstall

the breather. Capacity is about 5/8 quart (0.6

liters).