6 Operating Procedures

2. Deflector Positions:

The three external deflectors control the

size of the spread.

DWG. NO. 6020

Raising any of the three external deflectors

at the bottom of the discharge chute will pro-

duce a wider, thinner distribution of material to

that same side. Adjust the various speeds and

settings one at a time to produce the desired

spread pattern.

SWING AWAY CHUTE

Hiniker spreaders are equipped with a swing

away chute making cleaning of the hopper and

storage much easier. The swing away chute is

for clean out and storage only. Do not drive mo-

tor vehicle with swing away chute open or not

fully engaged in its working position.

SLIDE

REARWARD

1

2

DWG. NO. 6021

SPREAD CONTROL

Thickness of material cover is controlled by four

variables:

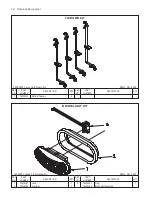

1. Feedgate Setting:

Raising or lowering the feedgate will in-

crease or decrease the amount of mate-

rial delivered to the spinner for any given

conveyor speed. Gate openings range from

3/8” to 4 1/4”.

DWG. NO. 6019

To set the feedgate position loosen the nut

at location 1. Use the feedgate handle to

move the feedgate into the desired posi-

tion. Lock the handle into position by re-

tightening the nut.

2. Conveyor Speed:

A faster conveyor speed will deliver more

material to the spinner.

3. Truck Speed:

The slower the vehicle travels, the more

material covers the ground.

4. Width of Spread:

A wide spread pattern produces a thinner

material cover.

Spread width is controlled by two variables:

1. Spinner Speed (determined by conveyor

speed):

A faster spinner speed produces a wider

pattern.