www.hi-velocity.com

© 1995-2017 Energy Saving Products Ltd.

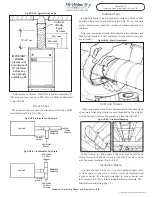

The return air duct is not supplied with the Hi-Velocity System.

It is to be supplied and installed by the contractor. The return air

and fresh air make-up ducts are to be installed according to local

building code.

The return air duct from the air handling units is to be

acoustically lined for sound absorption, for the first five feet, or

for the line of sight. This only applies on short return air duct work

of less than 10 feet (3.05m).

The return air is to be sized on a 0.15 static pressure (37 pa) as

compared to 0.10 static pressure (25 pa) for conventional forced

air systems. The maximum length for an individual return air duct

is fifty feet (15.24m).

Duct Sizing

Table RA-01 has recommended return air sizes for round and

rectangular ducts. A variance of

plus 20%

is allowable for sizing

return ducts that connect to the Hi-Velocity Systems unit.

Where allowed by local codes, a single return air grill may be

used. Note: Return air grill must have equal minimum of free air

area to return air.

Return Air

Table RA-01 – Return Air Duct Sizes

Unit

Rigid Ø

Flex Ø

Min Sq.

Inches

(Sq. cm)

50/51/52

12”

(305mm)

14”

(356mm)

120

(774cm)

70/71

12”

(305mm)

14”

(356mm)

120

(774cm)

100/101

14”

(356mm)

16”

(406mm)

168

(1084cm)

Remember: When using flexible duct for return air, use

one duct size larger due to the higher friction loss.

Module RAI

Return Air Installation (1/2)

Please note: It is VERY important NOT

to undersize the return air, as this will

create noise, increase motor power

consumption and reduce airflow.

Module RAI Return Air Installation (1/2)

When designing the return air for a Hi-Velocity System, there

are a few things to consider. It is common to use centralized return

air with systems that have rooms that are within a common area.

Separate floors or rooms that have high loads and require a large

amount of supply air flow should have their own return air, or be

tied into the centralized return air to allow the air to return back

to the fan coil. Rooms or areas that cannot be tied into the return

air should have an air transfer grill to allow the air to escape the

room and flow back to a centralized return air.

The Hi-Velocity System is a pressure supply duct system that

forces the air into rooms through supply outlets. A closed room

will pressurize, and air will escape through the undercut of a door

back to a centralized return air. (i.e. a typical bedroom with two

2” outlets or 1 HE outlet will deliver 64 cfm into the space, a 1/2”

undercut door will provide 15 square inches of r/a from the space

at a transfer velocity of 4 fpm, sufficient to provide comfortable

r/a.) If more than four 2” or two HE vents are installed in a room,

or if there is a sealed door in the room, an air transfer grill or

return air should be installed to allow the air back to the fan coil.

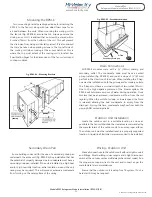

Once the placement of the return has been decided, the

return air knockout(s) can be cut. (Fig. RA-01) The pre-measured

guide cuts supplied with the fan coil should always be used; this

will guarantee maximum airflow across the coil.

Return Air Cutout

Fig. RA-01 - Return air cutout

Table RA-02 – Return Air Cutout Dimensions

Model

Dimensions

50/51 H/BU

9

1/2

” X 13

1/2

”

(241mm X 343mm)

70/71 H/BU

14” X 13

1/2

”

(356mm X 343mm)

100/101 H/BU

20” X 14”

(508mm X 356mm)

Important: When using flexible duct for

return air, use one duct size larger due to

the higher friction loss.

-19-