www.hi-velocity.com

© 1995-2017 Energy Saving Products Ltd.

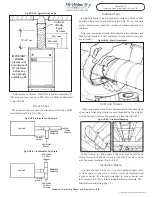

*Note: FZ to FZ

recommended to be wired to Freeze Stat (Anti-Ice Control). For chilled water applications, a jumper between FZ to

FZ must be installed to complete the Y2 - 24V Signal to Y on Condenser.

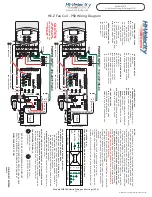

HE-Z Fan Coil - PSB Circuit Board Wiring

24 VAC Input terminals (tstat connections):

W1:

1st stage Heating, Runs at the heating speed when 24v (R) is supplied, set by the heat trim

pot.

W2:

2nd stage Heating, Runs at the heating speed when 24v (R) is supplied, set by the heat

trim pot. The difference between a W1 call and a W2 call is the output terminal that will be

energized with 24v. (W1 energized on t-stat terminal strip will provide 24v to W1 on output

terminal strip, W2 energized on t-stat terminal strip will provide 24v to W2 on output ter

-

minal strip,)

C:

Common

G:

Constant Fan, Runs at the Constant Fan speed when 24v (R) is supplied, set by the Fan trim

pot.

R:

24 volt supply

(Note: As long as Transformer is connected & the Fire Disconnect/Jumper Pin Header is

Present)

Y2:

2nd stage Cooling, Runs at the Cooling speed when 24v (R) is supplied, set by the Cool trim

pot.

Y1:

1st stage Cooling, Runs at the Cooling speed when 24v (R) is supplied, set by the Cool

trim pot. The difference between a Y1 call and a Y2 call is the output terminal that will be

energized with 24v. (Y1 energized on t-stat terminal strip will provide 24v to Y1 on output

terminal strip, Y2 energized on t-stat terminal strip will provide 24v to Y2 on output terminal

strip,)

D:

Runs at 70% Cooling speed when 24v (R) is supplied, set by the Cool trim pot.

O/B:

Heat Pump Reversing

Fan Speed Priority Sequence (from highest to lowest):

D=1st Y=2nd W=3rd G=4th

24 VAC Output terminals (24v output connections):

R:

24 volt Supply

(Note: As long as Transformer is connected & the Fire Disconnect/Jumper Pin Header is

Present)

C:

Common

Y1:

1st Stage Cooling Equipment

Y2:

2nd Stage Cooling Equipment*

W2:

24v Output to 2nd Stage Heating Equipment.

W1:

24v Output to 1st Stage Heating Equipment.

FZ:

Freeze Stat Connection*

FZ:

Freeze Stat Connection*

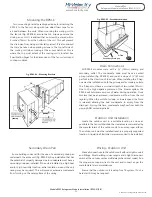

-24-

Module WIR

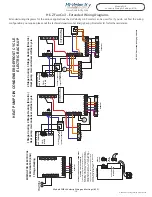

Hi-Velocity Wiring & Settings (4/10)

Module WIR Hi-Velocity Wiring and Settings (4/10)