www.hi-velocity.com

© 1995-2017 Energy Saving Products Ltd.

The Electrical Strip Heater (ESH) is an electric resistance heater

that slides into the fan coil on the leaving air side (supply side)

of the blower. This heater can be used for primary heating or

supplemental heat (auxiliary heating) for heat pumps. The ESH has

“0” clearance to combustibles, and requires minimum clearances

on the access side for maintenance and servicing (see Fan Coil

Placement: Module FCP). Allow 18” minimum of straight plenum

duct from the supply of the air handler before any branch outlets,

tees or elbows.

The ESH elements are rated for 240V 60 Hz. Higher voltages

are not recommended. When lower voltages are supplied, de-rate

the capacity of the ESH accordingly. 230V = 92%, 220V= 84%,

208V = 75%. Use only wires suitable for 167° F (75°C).

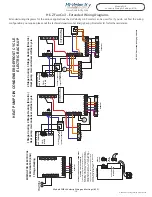

Wiring the Electrical Strip Heater

Electrical Strip Heater

Table ESH-01

Kw

Volts/

Phase

# of

feeders

Circuit

Breakers

5

240/1

1 X 20.8

1 X 30A

10

240/1

1 X 41.6

1 X 60A’

15

240/1

1 X 20.8 1 X 41.6

1 X 30A 1 X 60A

18

240/1

1 X 31.2 1 X 41.6

1 X 40A 1 X 60A

20

240/1

2 X 41.6

2 X 60A

23

240/1

2 X 47.0

2 X 60A

Installation

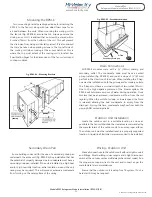

The ESH is labeled with a directional airflow sticker; when

placing the ESH, the sticker shall be in the direction of the air flow.

There is a minimum air flow requirement for the electric strip

heater:

The HE-B/HE-Z/HE/HV-50 fan coils and the HE-B/HE-Z/HE/HV-

70 fan coils require a minimum of six 2”x10’ AFD outlets per 5 kW.

The HE-Z/HE/HV-100 fan coils require a minimum of seven

2”x10’ AFD outlets per 5 kW.

*

One HE x 10’ AFD is equivalent to two - 2” x 10’ AFDs

Remove the shipping covers and inspect the heater carefully.

Check the ESH for any shipping damage, check the heating

elements for any loose connections and check all porcelain

insulators for any breaks. Report any damage to the manufacturer.

DO NOT INSTALL DAMAGED HEATER.

Module ESH

Electrical Strip Heater Installation (1/2)

Module ESH Electrical Strip Heater Installation (1/2)

PLEASE NOTE: THE ESH MUST BE WIRED TO A

DEDICATED BREAKER, SEPARATE FROM THE FAN COIL.

Install the ESH in the supply air side of the fan coil. Remove the

coil access door and simply slide the coil into place. The heating

elements (Fig. 01) must always be installed horizontally. Seal the

void between the fan coil and the ESH with the foam tape supplied

with the unit or with a suitable sealant. Mount the ESH onto the

fan coil cabinet with 4 self tapping screws from inside the ESH

wiring access door. Seal any additional openings with a suitable

sealing compound.

The air handler and the ESH must have independent power

supplies.

Disconnect all power sources before opening

the control box and working within.

Wires shall be sized

according to local electrical codes and ordinances. All wires must

be brought in through knock-outs. See Table ESH-01 for feeder

quantity of feeder ampacity.

The ESH 5 and 10 kW units have one single 240V breaker; the

15 kW to 23 kW units come complete with two supply circuit

breakers. These two circuits can be joined together using a Jumper

Bar (Square D® – QOU14100JBAF, not supplied) designed to use

one pair of larger gauge wire instead of two smaller gauge wires.

Install as per manufacturers guide lines, and according to code. A

disconnect switch close to the heater will be required.

Do not install ESH as shown, with

controls on top

Control circuit wiring between the heater terminals #1 and #2

on the ESH use Class 2 - 18 gauge wire to the zone valve terminals

in the fan control box.

Fig. ESH-01 - Do not install elements Vertically

-38-