5 - Operation

87

Spray Boom

Safety Info

Keep the spray boom in folded position while driving outside the field. Park the sprayer and tractor on level ground before

using the folding/unfolding functions.

Failure to comply will damage the boom and cause dangerous situations to people and the surroundings.

€

DANGER! Before unfolding the boom it is important to connect the sprayer to the tractor’s hitch point to prevent

overbalancing of the sprayer. Activate the tractor’s handbrake.

€

DANGER! When folding or unfolding the boom, make sure that no persons or objects are within the operating area

of the boom.

€

DANGER! Always follow the guidelines listed below when driving in areas with overhead power lines:

Keep from using the folding/unfolding functions in areas with overhead

power lines. Unintended boom movements may cause contact with

overhead power lines, causing a risk of fatal accidents.

ATTENTION! A label (HARDI item no. 978448) follows the sprayer.

This label must be placed in the cabin visible from the operator’s

seat.

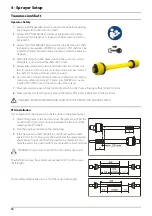

Operating the Grip

The buttons on the grip in the tractor controls the following sprayer functions in the field:

A.

Status light for power ON/OFF.

The light must be ON.

B.

Boom tilt up/down - left boom side.

Adjust the boom height individually for the right and left boom

side, if the terrain is hilly.

C.

Boom tilt up/down - right boom side.

D.

Boom slant - left boom side.

Adjust the boom height to match the slope, when driving across a

hillside.

E.

Boom slant - right boom side.

F.

Main ON/OFF for spraying.

Turn it ON for spraying, OFF to stop spraying.

G.

Boom height up.

Aim for a height of 50 cm above the crop when spraying.

H.

Boom height down.

I.

Boom sections spraying ON/OFF.

Switch pushed up is OFF; down is ON.

J.

Not used.

Summary of Contents for MEGA VPZ MASTER

Page 4: ...1 EU Declaration 4...

Page 10: ...Table of Contents 10...

Page 42: ...2 Safety Notes 42...

Page 68: ...3 Description 68...

Page 118: ...5 Operation 118...

Page 121: ...6 Maintenance 121 Lubrication Plan Boom Centre Close up of Glide Shoes to be Lubricated...

Page 172: ...8 Technical Specifications 172...

Page 176: ...Index 176...

Page 178: ...HARDI INTERNATIONAL A S Herthadalvej 10 DK 4840 N rre Alslev DENMARK...