-D2 -19

TURNING THE MACHINE ON

3_5b M717

5-1b

DANGER: To reduce the risk of electric shock.

Never leave the machine unattended when plugged in.

Always unplug this machine from the electrical outlet immediately after use and before per-

forming any maintenance on it.

WARNING: To reduce the risk of burns, fire, electric shock, or injury to persons.

Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

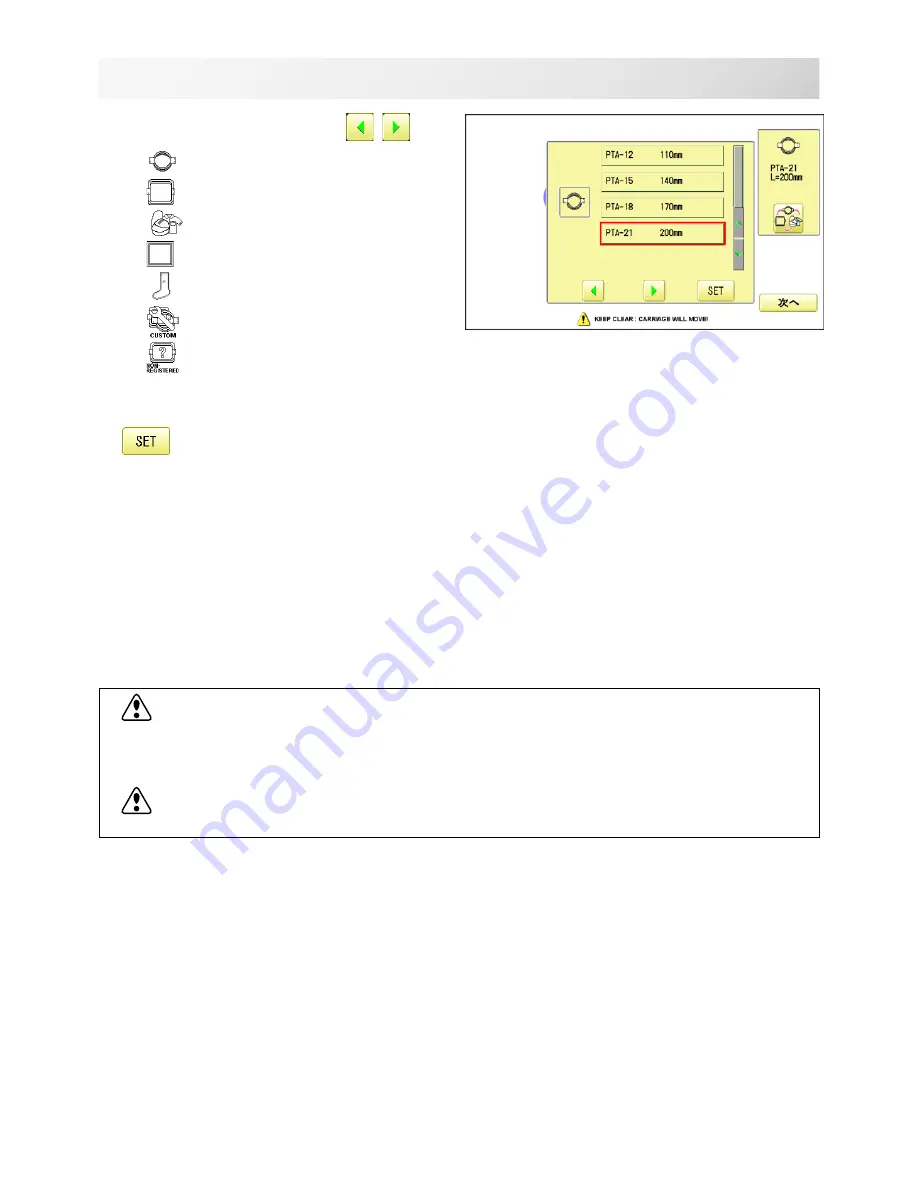

5. Select the desired frame with

.

: Tubular round frame

: Tubular square frame

: Cap and One-point frame.

: Border frame (for HCD2)

: Sock frame

: User-defined frame

: Non registered

6. Select desired type of frame and Press

.

The display returns to the view of Step 3.

To disconnect, switch the power switch to the

off position, then remove plug from outlet.