Hansa C27EU O&M Manual

– OM-023 Revision A 16/10/19

© Hansa Chippers 2019

15

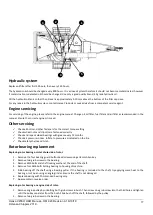

Belt tension adjustment

Using two 24 mm spanners, unlock the two locking nuts

from above the adjustment block on the engagement

handle by turning the top nut anti clockwise and the

bottom nut clockwise. Then move both locking nuts

upward along the thread.

From the fully disengaged position, gently turn the

engagement handle clockwise until you feel it start to

resist. From this position, turn the engagement handle

two full revolutions in the clockwise direction, or until

there is a significant resisting force on the handle (there

should be about 5 mm deflection when pressing firmly

on the belt). This is the recommended tension for the

belt drive when in the fully engaged position.

Note

: For new belts, allow another half revolution as the

tension will need to be increased after belt wear.

Using two 24 mm spanners, screw the two M16

adjustment nuts downwards until they touch the

adjustment block. Then turn the top nut clockwise and

the bottom nut anti clockwise simultaneously to lock

the nuts in place.

The new belts will wear into the pulley. Recheck the belt

tension after 10 hours of machine operation, and if

necessary, adjust them to the correct tension by

repeating this process.

Belt replacement

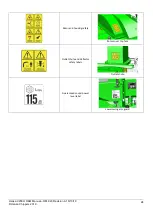

If the belts in your chipper look similar to any of the following images or are clearly broken, then they need to be replaced.

1

2

3

Adjustment

block

Adjustment

nuts

Adjustment

block

Adjustment

nuts

Cracked underside of belt

Sidewall belt wear

Soft, swollen belt

Worn cover on back of belt

Split belt cover