Hansa C27EU O&M Manual

– OM-023 Revision A 16/10/19

© Hansa Chippers 2019

16

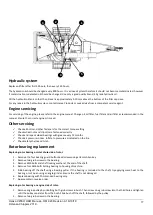

If a belt change is necessary, follow these steps

Using a 5 mm Allen key, unbolt and remove the pulley

guard (6 x M8 cap screws).

Turn the engagement handle counter clockwise until the

belt is fully disengaged. Remove old belts and replace (3 x

B46 vee belts).

Note:

The belts pass in between the idler wheel and belt

guide on the tensioner arm.

Note:

Engine not shown in this view.

Fasten the pulley guard back into place. Ensure belts are

properly tensioned (follow the ‘Adjusting

be

lt tension’

process on page 15) before starting the chipper.

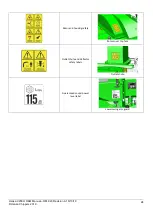

Greasing bearings & pivot points

Points that need to be greased are as follows (as per the diagram on the following page).

1.

Two bearings on the rotor shaft, one under the engine cover and the other above the inlet opening

2.

Two bearings on the feed roller

3.

Two bearings on either side of the feed roller pivot

4.

Outlet chute swivel, two grease nipples

5.

One grease nipple on the engine engagement screw

These points must be greased every 50 operating hours. Ensure a suitable grease is used (bearing grease or all-purpose grease).

1

2

3

Tensioner arm

Belt guide

Idler Wheel