Hansa C27EU O&M Manual

– OM-023 Revision A 16/10/19

© Hansa Chippers 2019

7

Safe operating procedures

Wear safety equipment:

Safety glasses and earmuffs must be

worn at all times

Wear work gloves:

The wearing of work gloves is optional but

highly recommended - ensure that the gloves fit tightly

Do NOT

wear loose fitting gloves or gloves with long cuffs

Loose gloves may get snagged by branches, which could result in the operator being pulled into the chipper

Tie long hair up

Long hair could be snagged by a branch and may be pulled into chipper

Wear clothes that sit tightly

Avoid scarves and any items that can get caught in the chipper or snagged on branches

Place the chipper on even ground and direct outlet chute onto soft ground

Ensure exhaust is pointing away from the working area and downwind from the operator and onlookers

Keep proper balance and footing at all times and stand at the same level as the chipper

Do NOT

climb onto the inlet table to push material into the feed roller

Keep your face and body away from the inlet chute. Stand to the side of the inlet table while feeding material into the

chipper

Standing to the side gives better access to the control bar and helps in keeping clear from flying debris

Feed only freshly cut material into the chipper

Do NOT

feed in materials covered in gravel, stones and dirt as this can rebound, injure the operator and damage

the machinery

Prune to a size that suits the chipper

’s capabilities

Pre-cut side branches

T

he branch will ‘self

-

feed’ more efficiently

Keep the engine clean of debris and other accumulations

This prevents damage to the engine or possible fire

Feed limbs and branches through butt end first, leaving the bushy head on

This helps guide the limb down the inlet chute

It reduces spinning and the occurrence of ejection of small pieces back up the inlet chute

Feed soft materials intermittently with branches

The wood chips tend to clean out any soft residue left in the chipper

The chipper can clog up with soft, wet or fibrous materials

Keep well clear of the outlet chute discharge area, even when the chipper is not currently processing material

High velocity, sharp discharge can cause serious injury

Keep the outlet free of blockage

If blockage occurs, turn the engine off and wait for rotor to stop spinning. Open the outlet chute and remove

material until the outlet chute is clear

Keep the feed roller free of blockage

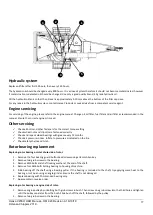

If blockage occurs, turn the engine off and wait for rotor to stop spinning. Remove the feed roller guard by

unhooking the four rubber latches. Unhook the springs from the base of the chassis. Lift the swing arm up and

insert the rotor pin (located underneath the control panel) into the tab on the housing to lock the swing arm in

place (as per the diagram below). You may now safely clear the blockage. Remove the rotor pin, lower the feed

roller, reposition the springs, then replace the guard

Turn off the engine whenever you leave the work area

DO:

Rotor pin

Feed roller motor

Swing arm