Hansa C27EU O&M Manual

– OM-023 Revision A 16/10/19

© Hansa Chippers 2019

13

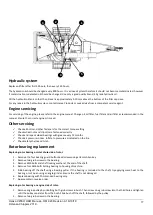

Reinstall the knives:

Clean all mounting surfaces and remount the

knives in the reverse procedure. Torque the

knife clamping nuts up to 190 Nm.

After sharpening, the width of the knives will

have been reduced, therefore the gap between

the knives and anvil may require adjustment.

There should be 3 mm of clearance between the

knife and the anvil. If there is not enough

clearance, the knife edge may touch the anvil

through deflection when cutting heavy

branches and damage the sharp edge. Too much

clearance will allow small twigs and fibrous

materials to be dragged through without being

cut.

To adjust the gap between the knives and the

anvil, first loosen the locking nuts from the

adjustment bolts on the anvil mounting plate

using a 16 mm spanner. Now tighten or loosen

the two adjustment bolts. Tightening these

bolts will cause the anvil mounting plate to slide

further along the slotted holes. Ensure you

tighten the two bolts evenly to avoid setting the

anvil on an angle.

Once the correct anvil position has been set,

ensure the locking nuts on the adjustment bolts

are tightened. Additionally, ensure the clamping

nuts are torqued to 44 Nm.

Remove the rotor pin and turn the rotor slowly

by hand to check that it turns freely.

Close and secure the outlet chute.

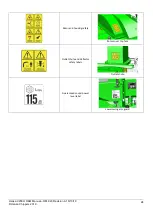

WARNING!

Every time the knife clamping bolts are torqued up to 190 Nm and loosened off again, the life of the

bolts is reduced. The knife clamping bolts must be replaced at most after every six sharpens. Contact Hansa for

replacement bolts (m16x50 countersunk bolts of grade 12.9 or higher). Use only genuine Hansa bolts.

5

6

7

Locking nuts

Rotor disk

Clamping bolts

Knife

Countersink

clamping bolts

Adjustment bolts

Anvil

Rotor

disc

Knife

3 mm

clearance

Bearing

Top view: Knife and anvil set-up

Spring washers