HAMWORTHY HEATING LTD

30

Wessex ModuMax

mk3

Boilers

500001308/C

from the casing by unfastening the 2 M6 nuts, to expose

the opening in the casing. The cleaning water and any

debris will exit the casing through this opening. On

completion ensure that the opening is clear of debris

and refit the condensate drain trap assembly, renewing

the gasket if required.

10.3.2

Should a high pressure hose not be available,

the heat exchanger will have to be removed from the

module casing. Isolate the heat exchanger from the flow

and return water pipework and drain down. Remove all

fittings from the water flow and return connections

(including sensors and pockets) and remove the safety

valve (if fitted) or ¾” cap. Unfasten the 10 M8 nuts

securing the water connection sealing plates and the

safety valve pipe sealing plate, and remove all sealing

plates and o

-

rings.

The boiler heat exchanger assembly is heavy, 97 &

116 weigh 100kg each & 147/196/254 weigh 130kg. It

is recommended that a suitable lifting apparatus is used

to support the weight of the heat exchanger, an M12

lifting eye nut can be fitted to the M12 stud at the top of

the heat exchanger front plate for this purpose. Before

connecting the lifting equipment to the lifting eye, hang a

new heat exchanger to casing sealing gasket over the

lifting eye, with the adhesive side facing the boiler. This

will enable the new gasket to be fitted on re

-

assembly

without cutting it!

Remove the 6 M10 nuts that retain the heat exchanger

into the boiler module casing, and with the front end

supported slowly withdraw the heat exchanger until the

rear of the stainless steel baffles are visible. With the

rear of the heat exchanger resting in the body of the

boiler and the front supported by the lifting apparatus,

access is gained for removal of the stainless steel

baffles. The silicon sealant between the baffle and the

end plates must be peeled away, before attempting to

remove the baffles. Unhook the stainless steel springs

and remove the baffle plates to expose the finned tube

bank. Wire brush both sides of the baffles to remove

any deposits. Thoroughly wire brush the finned tubes

and ensure that all debris is removed from the centre of

the heat exchanger.

Remove the heat exchanger from the boiler body.

The heat exchanger tubes are stainless steel.

Remove the bolts and nuts securing the heat exchanger

front cover plate. Remove the bolts securing the heat

exchanger rear cover plate. Clean and de

-

scale all

surfaces of the heat exchanger tube header castings

and cover plates, and internal surfaces of the finned

tubes and water connection nipples. Chemical de

-

scaling is preferred for the tube bank assembly.

Note:

Always follow the chemical manufacturer’s

instructions to ensure correct application and safety.

Re

-

assemble the baffle plates by fitting one of the

stainless steel springs and inserting the baffles beneath

it, then fitting the second spring. When all the baffles are

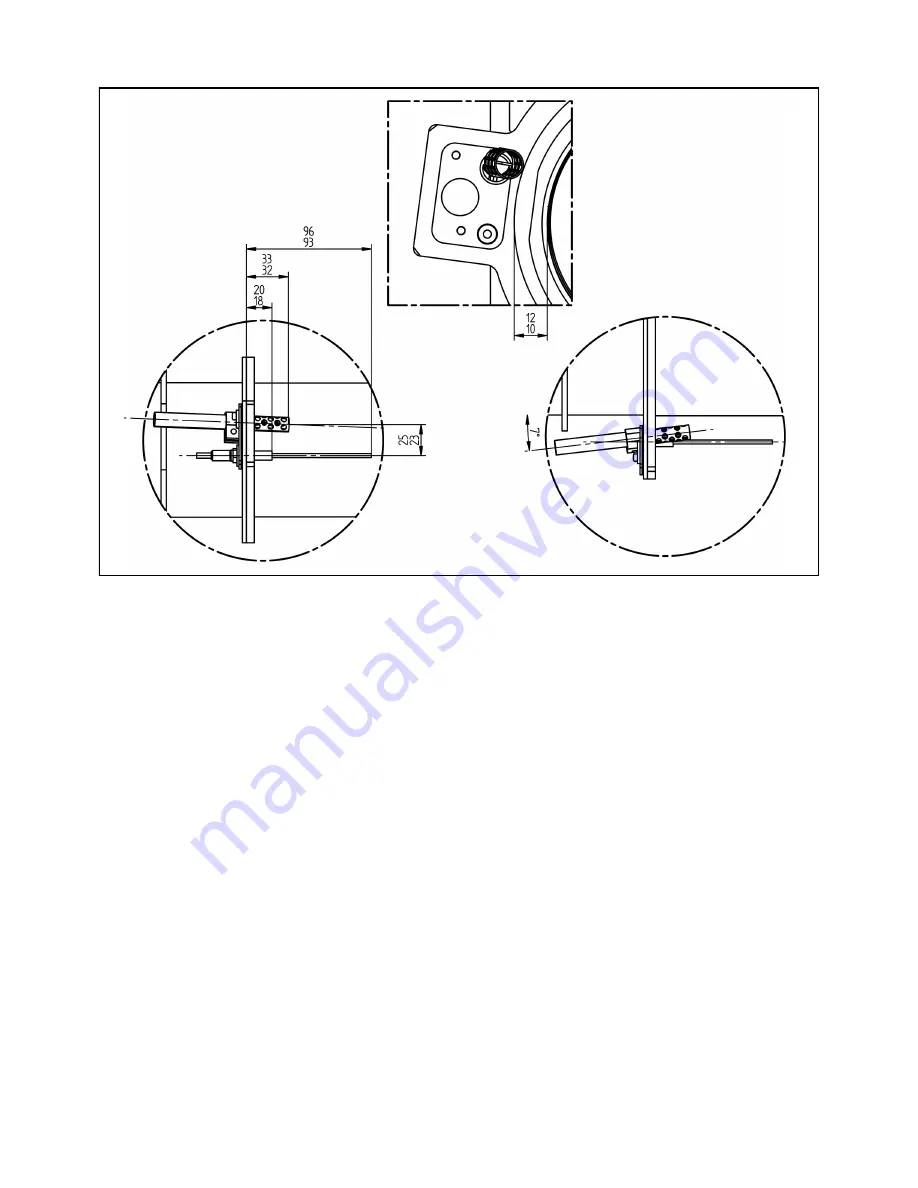

Figure 10.2

-

Hot Surface Igniter and Flame Sensing Probe Positions