035-17477-002 Rev. D (1202)

14

Unitary Products Group

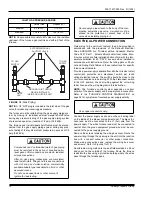

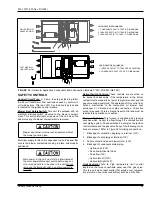

ACCESSORY CONNECTIONS

The furnace control will allow power switching control of vari-

ous accessories. Refer to Figure 15, for connection details.

ELECTRONIC AIR CLEANER CONNECTION

Two 1/4" spade terminals (EAC and EAC N) for electronic air

cleaner connections are located on the control board. The

terminals provide 115 VAC (1.0 amp maximum) during circu-

lating blower operation.

HUMIDIFIER CONNECTION

Two 1/4" spade terminals (HUM and HUM N) for humidifier

connections are located on the control board. The terminals

provide 115 VAC (1.0 amp maximum) during heating system

operation.

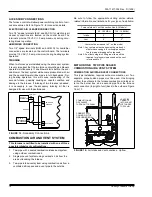

TWINNING

When two furnaces are installed using the same duct system,

it is very important that the two furnace circulating air blowers

operate simultaneously. If one blower starts before the sec-

ond blower, the duct system will become pressurized with air

and the second blower will be made to turn backwards. Dur-

ing heating operation, this will cause overheating of the

second furnace, possibly causing an unsafe condition and

damage to the furnace. If twinning of two furnaces is desired,

it is necessary to use the accessory twinning kit that is

designed for use with these furnaces.

COMBUSTION AIR AND VENT SYSTEM

1.

Two-pipe with a sealed combustion intake/vent system

using outdoor combustion air.

2.

Single pipe vent system using combustion air from the

area surrounding the furnace.

3.

Two-pipe intake/vent system using combustion air from a

ventilated attic space and a vent pipe to the outside.

Be sure to follow the appropriate venting section details,

related information and limitations for your type of installation.

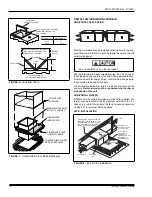

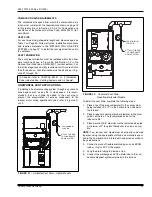

METHOD ONE: TWO PIPE SEALED

COMBUSTION AIR & VENT SYSTEM

COMBUSTION AIR INTAKE/VENT CONNECTIONS

This type installation requires outdoor combustion air. Two

separate, properly-sized pipes must be used. One bringing

air from the outdoors to the furnace combustion air intake col-

lar on the burner box, and a second pipe from the furnace

vent connection (top right of unit) back to the outdoors.Figure

16 or 17.

FIGURE 15 :

Accessory Connections

This furnace is certified to be installed with one of three

possible intake/vent configurations.

115 VOLT

HUMIDIFIER

115 VOLT

ELECTRONIC

AIR CLEANER

BLK

WHT

EAC HOT

HUM. HOT

BLK

WHT

EAC

HUM

EAC

HUM

NEUTRALS

SWITCHED

CIRCUITS

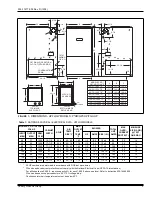

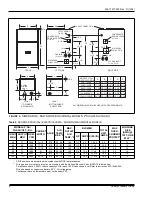

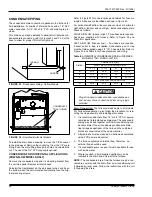

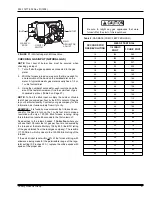

Furnace Intake / Vent Connection Size (All Models)

40 - 100 MBH

120 - 140 MBH

Intake

2”

3"

Vent

2”

2"

*

*.

Vent must be increased to 3" on this model.

Note 1:Any vent pipe size change must be made out-

side furnace casing in a vertical pipe section

to allow proper drainage of condensate.

Note 2: An offset using two 45 degree elbows will be

required for plenum clearance when the vent

is increased to 3”.

FIGURE 16 :

Air Intake and Vent Locations - Upflow

VENT PIPE

CEMENTS

INTO SOCKET

JUST UNDER

TOP PANEL

COMBUSTION AIR

PIPE PASSES

THROUGH TOP PANEL

CONNECTS TO

COLLAR ON TOP

OF BURNER BOX