035-19592-001 Rev. C (0204)

2

Unitary Products Group

7.

NEVER . . .Store flammable materials of any kind near your fur-

nace. Gasoline, solvents, and other volatile liquids should be

stored only in approved containers outside your home. These

materials vaporize easily and are extremely dangerous.

8.

NEVER . . .Store cleaning materials near your furnace. Materials

such as bleaches, detergents, powdered cleansers, etc., can

cause corrosion of the heat exchangers.

9.

NEVER . . . Use the area around your furnace as a storage area

for items which could block the normal flow of air. This flow of air is

required for ventilation of the various furnace components.

INSTRUCTIONS FOR EXAMINING THE FURNACE

INSTALLATION

It is the owner’s responsibility to ensure that an annual inspection of the

entire heating portion of the unit is made by a qualified service agency.

1.

Examine the heating exchanger, vent/combustion air piping, vent

connectors and chimney to be sure they are clear and free of

obstructions.

2.

Examine the vent pipe making sure it is in firmly place, that it

slopes slightly upward and is physically sound without holes and

all of the connections are secure.

3.

Examine the return-air duct connections to make sure they are

physically sound, sealed to the furnace casing, and the ducts ter-

minate outside the space containing the furnace.

4.

Examine the furnace casing making sure the physical support is

sound without sagging, cracks or gaps. Examine the furnace base

making sure it is physically sound without cracks, gaps or sagging

and has a good seal.

5.

Examine the furnace casing for obvious signs of deterioration.

6.

Examine the burner flames to make sure they are in good adjust-

ment. Refer to the pictorial sketch shown in Figure 2 as a compari-

son to the actual flame.

7.

Examine the furnace as outlined above in steps “1 - 6” before

each heating season. Use Figure 3 for visual reference.

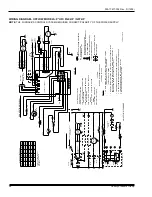

FIGURE 1:

Component Locations

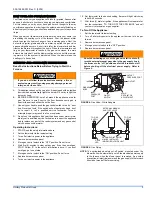

FIRE OR EXPLOSION HAZARD

This furnace is designed and approved for use with Nat-

ural Gas and (LP) Propane Gas ONLY. DO NOT BURN

ANY LIQUID FUEL OR SOLID FUEL IN THIS FURNACE.

Burning any unapproved fuel will result in damage to the

furnace heat exchanger, which could result in Fire, Per-

sonal Injury, and/or Property Damage.

BURNER BOX

GAS VALVE

VENT PIPE

CONDENSATE

DRAIN SYSTEM

INDUCER

ASSEMBLY

CONTROL

BOARD

PRESSURE

SWITCH

BLOWER

INDUCER

MOTOR

FIGURE 2:

Burner Flame Drawing

COMBUSTION AIR

INTAKE

BURNER

FLAME

MANIFOLD

INNER FLAME

CONES

MAIN

BURNER

FIGURE 3:

Furnace Examination Checkpoints

EXAMINE ENTIRE

FURNACE CASING

SHOWN IN ALL

DRAWINGS

EXAMINE

RETURN-AIR

DUCT CONNECTION

EXAMINE

RETURN-AIR

DUCT CONNECTION

REMOVE PANEL

TO EXAMINE

BURNER FLAMES

EXAMINE

FURNACE

CASING

EXAMINE

FURNACE

CASING

EXAMINE EXTERNAL

VENT PIPE

EXAMINE HEAT EXCHANGER

INTERNAL VENT COMBUSTION

AIR PIPE. MUST REMOVE PANEL

TO EXAMINE.

3

3

2

6

5

4

4

(SIDE OR BOTTOM)