035-17477-002 Rev. D (1202)

Unitary Products Group

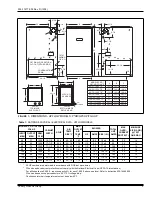

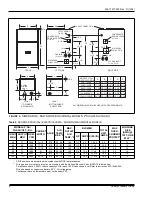

11

This appliance is design certified for line contact for furnaces

installed horizontally. The intersection of the furnace top and

sides form a line. This line may be in contact with combustible

material. Refer to the "SPECIFIC UNIT INFORMATION" sec-

tion of this manual for further information on installation loca-

tion and limitations.

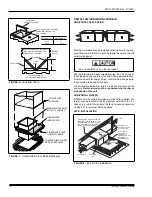

Secure a platform constructed of plywood or other building

material to the floor joists.

NOTE:

In either a horizontal left or right installation, a mini-

mum of 8" clearance is required beneath the furnace to allow

for the installation of the condensate trap and drain pipe.

Refer to "CONDENSATE PIPING" section of this manual for

more information.

NOTE:

See crawl space installation for suspending the fur-

nace in attic installations.

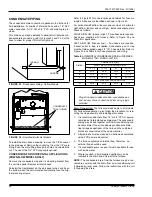

CRAWL SPACE INSTALLATION

The furnace can be hung from floor hoists or installed on suit-

able blocks or pad. Blocks or pad installations shall provide

adequate height to ensure the unit will not be subject to water

damage.

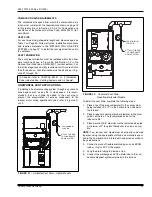

When suspending the furnace from rafters or floor joists using

rod, pipe or straps, refer to the Physical and Rating Data

Table for downflow/horizontal furnace weights to determine

suitable means of suspension.

Angle supports should be placed at the supply air end and

near the blower deck (Refer to Figure 9 ).

Do not support

at return air end of unit.

Units may also be suspended by using straps or other mate-

rial at the same location. All four suspension points must be

level to ensure quiet furnace operation.

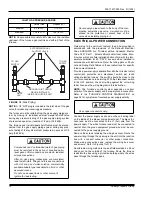

GAS PIPING

The gas supply should be a separate line and must be

installed in accordance with the National Fuel Gas Code,

ANSI Z223.1 (latest edition), or the CAN/CGA B149.1 or .2

Installation Codes (latest edition) and all applicable local and

utility requirements.

Some utility companies or local codes require pipe sizes

larger than the minimum sizes listed in these instructions and

in the codes. Properly sized wrought iron, approved flexible

or steel pipe must be used when making gas connections to

the unit. The installation of a drop leg and ground union is

required (refer to Figure 10).

Gas piping may be connected from either side of the furnace

using any of the gas pipe entry knockouts on both sides of

the furnace (refer to Figures 1 or 2 for locations and dimen-

sions).

NOTE:

Plan your combustion air piping before determining

the correct gas pipe entry. Use 90 degree service elbow(s), or

short nipples and conventional 90 degree elbow(s) to enter

through the cabinet access holes.

If this furnace is installed over a finished space, a

condensate safety pan must be installed.

When a furnace is installed in an attic or other

insulated space, keep all insulating materials at

least 12" away from furnace and burner combus-

tion air openings.

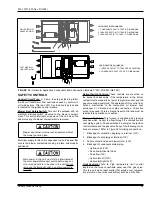

FIGURE 9 :

Typical Furnace Installation Using

Suspension Materials

1” MAX. BETWEEN

ROD & FURNACE

SUPPORT

ROD

6” MIN BETWEEN

ROD & FURNACE

1” MAX. BETWEEN

ROD & FURNACE

ANGLE IRON

BRACKET

In any application where temperatures below

freezing are possible, see “BELOW FREEZING

LOCATIONS ” on page 4

An overpressure protection device, such as a

pressure regulator, which conforms to the National

Fuel Gas Code, ANSI Z223.1 (U.S.) or CAN-

B149.1 or.2 (Canada) and acts to limit the down-

stream pressure to a value that does not exceed

0.5 PSI (14" w.c.), must be installed in the gas pip-

ing system upstream of the furnace. Failure to do

so may result in a fire or explosion or cause dam-

age to the furnace or some of its components.