Supplied By www.heating spares.co Tel. 0161 620 6677

11

14

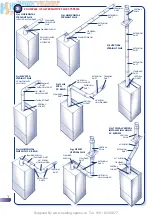

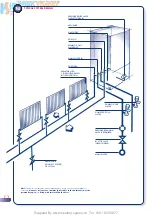

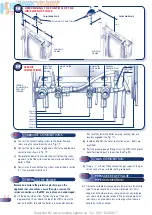

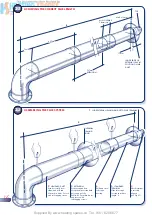

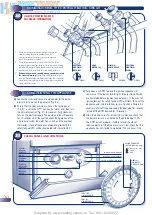

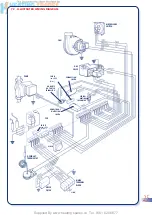

ALTERNATIVE METHODS OF FILLING A SEALED SYSTEM

EXPANSION VESSEL

The table below shows the maximum system volume that the

integral expansion vessel can sustain under different charge

pressure conditions. If the system volume exceeds that shown, an

additional expansion vessel must be fitted and connected to the

heating system primary return pipe as close as possible to the

appliance. If an extra vessel is required, ensure that the total

capacity of both vessels is adequate. Further details are available

in the current issues of BS5449 and BS6798.

NOTE

:

If the pressure gauge indicates 2.65 bar or greater when the

appliance is at maximum temperature with all radiators in circulation an

extra expansion vessel is required.

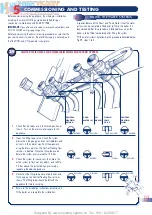

PRESSURE GAUGE

A pressure gauge is situated on the

appliance control panel. This can be viewed by lowering the

bottom front panel.

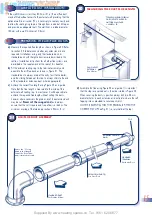

PRESSURE RELIEF VALVE

A pressure relief valve set at 3 bar

(43.5 psi) is supplied with the appliance.

a)

Check that the mains water pressure is sufficient to produce

the required DHW flow rate, but does not exceed the

maximum DHW pressure (10 bar). If necessary, a pressure

reducing valve must be fitted to the mains supply before the

DHW inlet connection.

b)

The final 600mm (24in) of the mains supply pipe to the boiler

must be copper.

c)

A domestic hot water regulator is fitted within the Finest group

set to control the maximum water flow rate. This may be

removed to obtain higher flow rates. Higher flow rates will not

damage the appliance but may reduce the water temperature

below an acceptable level.

d)

If the appliance is installed in an area where the temporary

hardness of the water supply is high, say over 150ppm, the

fitting of an in-line scale inhibitor may be an advantage.

Consult the Local Water Supplier if in doubt.

e)

For specific information relating to fittings (eg. Showers,

Washing Machines etc) suitable for connection in the DHW

circuit, consult the Local Water Supplier. However the following

information is given for guidance:

DOMESTIC HOT/COLD WATER SUPPLY TAPS AND

MIXING TAPS.

All equipment designed for use at mains

water pressure is suitable.

SHOWERS & BIDETS

. Any mains pressure shower or bidet

complying with the Local Water Undertaking bylaws is suitable.

a)

Wiring external to the appliance must be in accordance with

the current l.E.E. Wiring Regulations (BS 7671) for electrical

installation and any local regulations which apply.

b)

The mains cable must be at least 0.75mm

2

(24/0.2mm)

PVC Insulated to BS6500 table 16.

c) THIS APPLIANCE MUST BE EARTHED.

(Failure to provide

a satisfactory Earth connection will result in appliance

malfunction)

d)

The method of connection to the mains supply must facilitate

complete electrical isolation of the appliance. Either a 3A

Fused three pin plug and unswitched shuttered socket outlet,

both complying with BS1363, or a 3A fused double pole

switch having a 3mm contact separation in both poles and

serving only the boiler (and its external controls) may be used.

The appliance may be used with any Certificated mains voltage

room thermostat as described in section 4.

3.7

DOMESTIC HOT WATER SYSTEM

3.8

ELECTRICITY SUPPLY

3.9

EXTERNAL CONTROLS

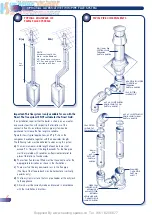

EXPANSION VESSEL REQUIREMENTS

Vessel charge and initial

system pressure

Total water content of system

using 7ltr. (1.54gal) capacity expansion

vessel supplied with appliance

For systems having a larger

capacity multiply the total system capacity

in litres (gallons) by the factor to obtain the

total minimum expansion vessel capacity required litres (gallons)

bar

0.5

1.0

1.5

psi

7.3

14.5

21.8

96ltr

73ltr

50ltr

21gal

16gal

11gal

0.0833

0.109 0.156

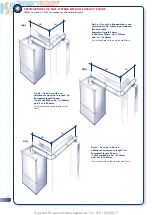

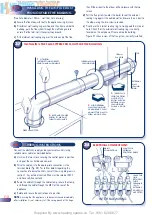

•

MAINS WATER

SUPPLY

•

•

HOSE

UNIONS

•

DOUBLE

CHECK

VALVE

ASSEMBLY

•

AIR INLET

VALVE

•

STOP

VALVE

•

HEATING SYSTEM

RETURN

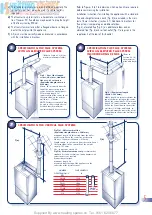

•

TEMPORARY

HOSE

•

TEST COCK

•

CISTERN &

OVERFLOW

•

MAINS

WATER SUPPLY

•

PRESSURE PUMP

& REDUCING VALVE

IF REQUIRED

•

STOP

VALVE

•

HEATING

SYSTEM

RETURN

METHOD A

METHOD B

Note:

The appliance has a built in

filling loop