Supplied By www.heating spares.co Tel. 0161 620 6677

ROUTINE SERVICING

6

33

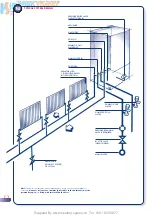

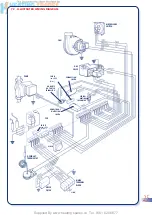

LOCATION OF

SERVICEABLE

COMPONENTS

6.1

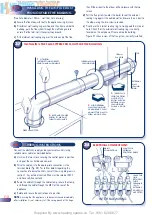

MAIN BURNER ASSEMBLY

6.2

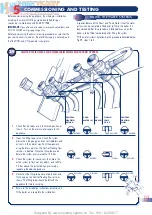

BURNER INJECTOR

6.3

IGNITION AND DETECTION ELECTRODES

6.4

FAN ASSEMBLY

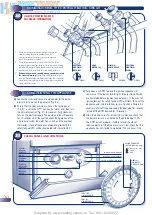

To ensure continued efficient operation of the appliance, it is

recommended that it is checked and serviced as necessary at

regular intervals. The frequency of servicing will depend upon the

particular installation conditions and usage but in general once a

year should be adequate. It is the law that any service work must

be carried out by a competent person such as British Gas or other

CORGI registered personnel.

The boiler incorporates a flue sampling point on the top panel in

front of the flue outlet. If the service engineer has suitable

equipment to analyse the flue gas, the plastic cap may be

removed and a 6mm inside diameter sample tube fitted. Do not

forget to replace the plastic cap after use.

Before commencing any service operation, ISOLATE the mains

electrical supply, and TURN OFF the gas supply at the main

service cock.

Service the appliance by following the full procedure detailed below:

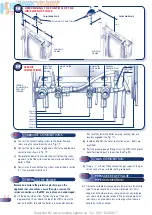

a)

Remove both casing front panels as follows: Pivot the lower

front panel downwards and pull forwards to release. Unscrew

the upper panel retaining screw and lift off the upper casing

panel.

b)

Remove the sealed chamber front panel (4 screws)

c)

Remove the nut securing the burner locating guide and burner

earth wire.

d)

Remove the combustion chamber front panel (7 screws).

Take care not to damage the insulation.

Do not attempt to light boiler with Front Panel removed.

e)

Unscrew and remove the two screws securing the control box

in the upright position and pivot the control box forwards.

f)

Remove the plug from the side of the control box and unclip

a)

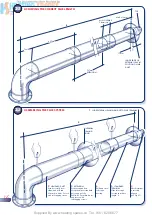

Check that the main injector is free from dirt and debris. If

necessary clean the injector orifice using a soft brush or

vacuum cleaner. Do not use a wire brush or any abrasive

material. It is not necessary to remove the injector unless there

is evidence of debris inside the orifice.

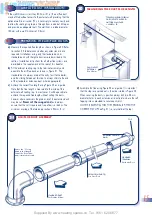

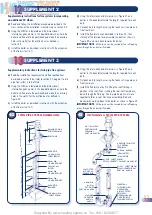

a)

Inspect the ignition and detection electrodes in situ. If

necessary clean using a soft brush.

If either the electrode or the ceramic insulation show signs of

damage or wear, replace the electrode(s).

b)

Check that the alignment of the ignition and detection

electrodes are as shown in Figure 35. Adjust by carefully

bending the tip of the electrode rod whilst supporting the base

of the rod. Do not put any pressure on the ceramic insulation.

a)

Carefully disconnect the tab connectors on the fan wiring from

the fan.

b)

Disconnect the air pressure switch sensing pipes from the fan,

noting their positions

c)

Remove the fan assembly by unscrewing the two screws,

lowering the assembly and lifting it forwards.

the grommet in the bulkhead below the burner to release the

earth, ignition, and detection wires.

g)

Remove the burner by sliding it forwards with reference to

Figure 34.

h)

Inspect and if necessary clean the main burner ports using a

soft brush or vacuum cleaner. Do not use a wire brush or any

abrasive material.

•

COMBUSTION CHAMBER

FRONT PANEL FIXING

SCREWS (7)

•

•

•

•

•

•

•

•

•

• • •

AUTO AIRVENT

FAN ASSEMBLY BASE

PLATE SCREWS

PUMP

GROUP SET

CONTROL

BOX

AIR PRESSURE

SWITCH & PIPES

DETECTION ELECTRODE

BURNER

IGNITION ELECTRODE

•

GAS CONTROL VALVE

•

•

GAS COCK

PRESSURE RELIEF

VALVE

FAN ASSEMBLY

•

PRESSURE

GAUGE

•

OVERHEAT THERMOSTAT

•

CONTROL PANEL

22