Supplied By www.heating spares.co Tel. 0161 620 6677

5.4

DOMESTIC HOT WATER FLOWRATE

5.5

FINAL CHECKS

32

FITTING THE CASING PANELS

5.6

IGNITION LOCKOUT

5.7

OVERHEAT THERMOSTAT

5.8

FROST PROTECTION

5.9

OTHER FEATURES

5.10

USERS INSTRUCTIONS

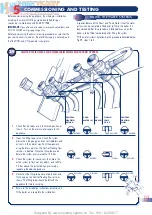

DHW flow rate is low. If modulation is suspected, open all

DHW taps to maximise flow and re-check burner pressure)

If it is necessary to adjust the DHW burner pressure the

method is described in section 9.6 Gas valve replacement.

e)

Close the DHW tap and ensure that the ‘burner on’ neon

(Fig. 31) goes off, the burner goes out, and the pump stops

after an overrun period.

f)

Ensure that the room thermostat (if fitted) is calling for heat.

Turn the heating control knob (Fig. 31) to maximum (fully

clockwise), then turn the clock override switch (Fig. 31) to

the

I

position. The burner will light.

NOTE:

that the central heating burner pressure is factory set and is not adjustable.

g)

Set the clock to the desired times by setting the tabs.

h)

Slide the clock override switch to the ‘timed’ (Auto) position and

check the operation of the clock and room thermostat (If fitted).

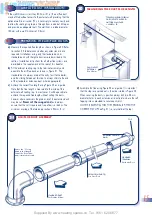

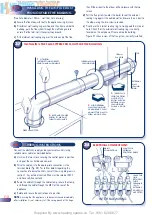

A flow regulator is supplied factory fitted to the appliance to ensure

that no adjustment is necessary. Should the mains flow rate be below

the minimum required it is possible to remove the flow regulator

from the appliance as instructed in section 9 (Fig. 38).

a)

Turn the appliance off and remove the manometer and

tighten the burner pressure test point screw. Re-light burner

and test for gas soundness.

b)

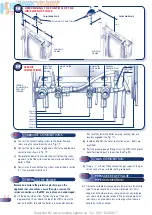

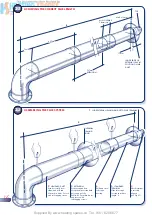

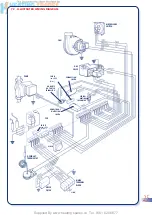

Fit the boiler casing as described and illustrated in Figure 32:

Fit each side panel (both are identical) with two screws at the

top and bottom of each panel. Fit the upper front panel in

position and locate by gently sliding it downwards over the

supporting tabs. Screw into position using the single fixing

screw at the top of the casing. Fit the lower front panel by

placing in a horizontal position, pushing it towards the boiler

ensuring that the locating pins are engaged, then rotating it

upwards - fit badge to front of casing.

c)

Set the heating and hot water controls (Fig. 31) to the required

settings. Ensure that the clock override switch is in the timed

position, and check that the time clock is set at the desired time

periods. Set the room thermostat (if fitted) to the required setting.

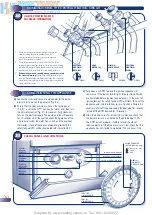

In the event of an ignition failure, the safety lockout LED will flash.

Turn off the electrical power supply to the appliance (or remove

the demand for heat - either CH or DHW), wait 10 seconds, and

restore the power supply (or demand for heat).

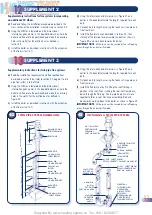

a)

This appliance is fitted with an overheat thermostat. In the event

of overheating, the appliance will shut down and the safety

lockout LED will light continuously. If an overheat condition occurs

allow the appliance to cool, then press the overheat reset button

once (located underneath the appliance at the left hand side).

a)

This appliance is fitted with a frost protection device. In the

event of very cold conditions (when the internal pipework

temperature falls below 5°C) the boiler will light for a few

minutes to protect the appliance and system from potential

frost damage.

The following additional features are included in the appliance

specification:

ANTI-CYCLE DEVICE

When the appliance cycles on it’s central heating control setting a

slow cycle device operates. This allows the water to heat up slowly

thus preventing rapid cycling of the burners.

ANTI PUMP SEIZURE DEVICE

Providing that a power supply is maintained, The pump will

operate for at least 20 seconds every 23 hours (regardless of heat

demand) to prevent pump seizure during periods where the

appliance is not used.

WATER FLOW SWITCH

This device prevents the burner from igniting if there is inadequate

water flow through the main heat exchanger.

Upon completion of commissioning and testing the system, the

installer should draw the user’s attention to the following.

a)

Give the ‘Users Instructions’ to the householder and

emphasise their responsibilities under the ‘Gas Safety

(Installation and Use) Regulations 1994’ (as amended).

b)

Explain and demonstrate the lighting and shutdown procedures.

c)

Advise the householder on the efficient use of the system,

including the use and adjustment of all system controls for

both DHW and CH.

d)

Advise the user of the precautions necessary to prevent

damage to the system, and to the building, in the event of the

system remaining inoperative during frost conditions.

e)

Explain the function of the boiler overheat thermostat, and

how to re-set it. Emphasise that if cut-out persists, the boiler

should be turned off and the installer or service engineer

consulted.

f)

Stress the importance of an annual service by a registered

heating engineer.

g)

The electrical mains supply to the appliance must remain on

for the frost protection circuit to operate.

•

FIT

BADGE

21