25

j)

Remove the 4 nuts holding the combustion chamber fr

ont

cover in place.

k)

Remove the gas contr

ol valve, fan & burner assembly, by

carefully pulling forward the combustion chamber front and

pivoting the assembly forward, then disengage the gas valve feed

pipe from the casing, by lifting up the assembly. Take care not to

damage the insulation.

l)

The assembly may then be inspected. If the gas valve is to be

replaced refer to section 9.3.

m)

Re-assemble in r

everse order.

6.3

BURNER

Inspect, and if necessar

y clean the main burner ports using a soft

brush or vacuum cleaner. Do not use a wire brush or any

abrasive material.

Inspect the inside of the combustion chamber for debris. If

necessary, clean the inside of the tubes with a soft brush. Do not

brush the insulation at the rear, check the integrity of the

combustion chamber insulation panels, if damaged they will

require replacement.

6.4

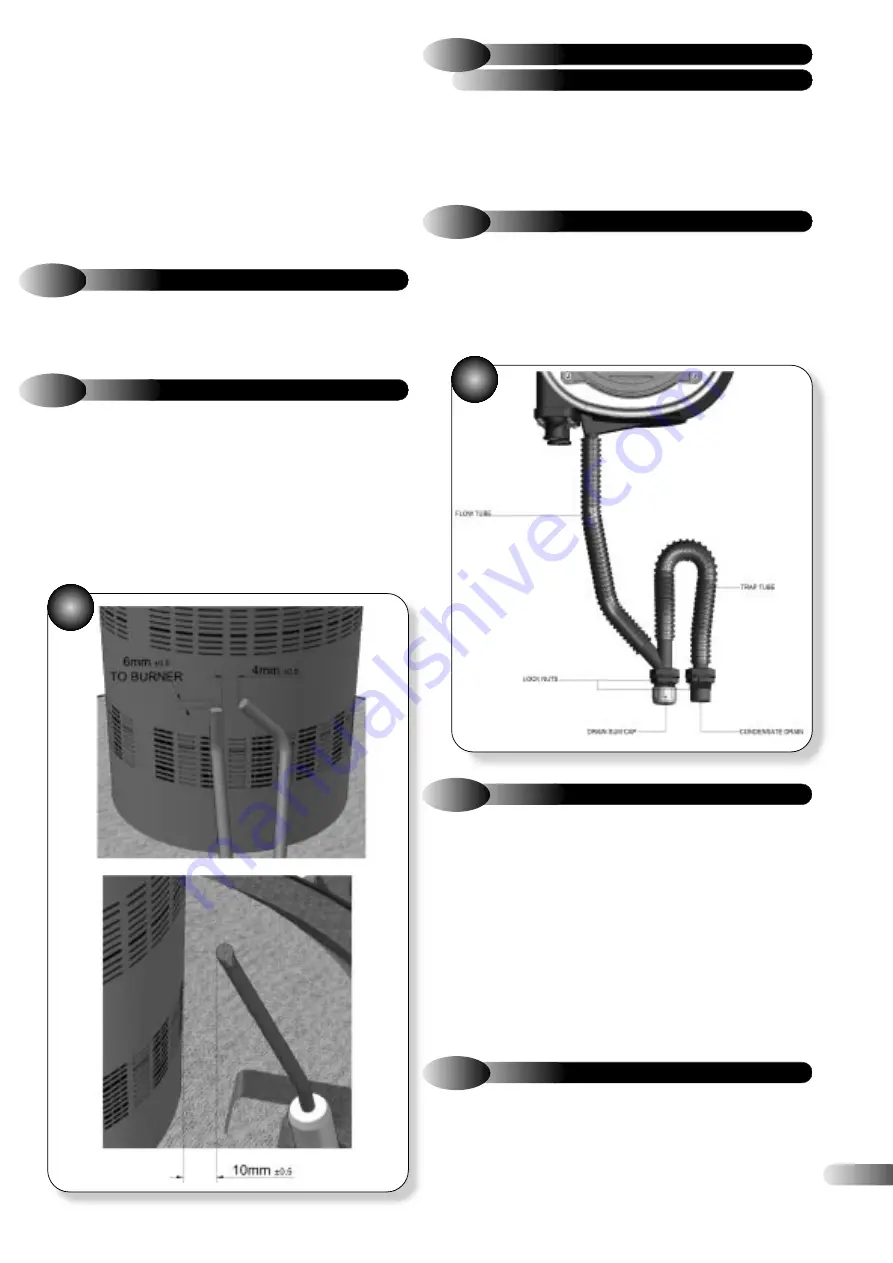

IGNITION & DETECTION ELECTRODES

a)

Inspect the ignition and detection electr

odes in situ. If

necessary, clean using a soft brush. If either the electrode or the

ceramic insulation shows signs of damage or wear, replace the

electrode(s) and their gasket.

b)

Check that the alignments of the ignition and detection

electrodes are correct. Refer to Figure 29. Adjust by carefully

bending the tip of the electrode rod whilst supporting the base of

the rod. Do not put any pressure on the ceramic insulation.

& HEAT EXCHANGER

6.5

COMBUSTION CHAMBER

The condensate Drain has a r

emovable cap, Figure 30, which

allows the removal of debris that may be caught within it. Place a

bowl under the cap to catch the condensate and remove the cap.

Any debris inside will be expelled at this point. Replace the cap

ensuring a good seal is made. Discard the condensate and debris.

6.6

CONDENSATE DRAIN

30

29

a)

Re-assemble all components in r

everse order.

b)

Check that all joints and seals ar

e correctly fitted.

c)

T

urn on the gas and electricity supply and light the appliance,

as described in section 5.2.

d)

Re-per

form a combustion check, as described in section 6.1.

e)

Check the operation of the appliance in both CH and DHW

modes as applicable.

f)

Remove the manometer and tighten the inlet pr

essure test

point sealing screw.

g)

T

est for gas tightness.

6.7

RE-ASSEMBLY & RE-COMMISSIONING

a)

Ensur

e the fascia panel is placed into the upright position and

secure with the two screws.

b)

Re-fit the fr

ont casing panel.

c)

Retur

n all appliance and external controls (if fitted) to their

original settings.

6.8

FINAL CHECKS