23

Rossi

Operating instructions − UTD.045.06-2013.00_TR_EN

TR

EN

of the parallel key is to be at least 0,9 times the pinion face width;

– mount onto the servo motor shaft end, in the following order:

– the

spacer

pre-heated at

65 °C

treating the relevant motor shaft

area with

adhesive type LOXEAL 58-14

and checking that

between keyway and motor shaft shoulder there is a cylindrical

part ground by 1,5 mm at least; pay attention not

to damage the

external surface

of spacer;

– the

key

in the keyway, making sure that a contact length of at

least 0,9 times the pinion width is present;

– the

pinion

pre-heated at

80 ÷ 100 °C

;

– the

axial fastening system

when foreseen (self locking screw

on motor shaft butt-end with washer and spacer or hub clamp

with 1 or more dowels, fig. a); for the cases foreseen

without

axial fastening

(fig. b), apply adhesive type

LOXEAL 58-14

also on the motor shaft part laying under the

pinion

;

– in case of axial fastening system with hub clamp and dowels,

make sure that they do not overhung from spacer external surface:

screw the dowels completely and, if necessary, imprint the motor

shaft with a point;

– grease (with grease type KLÜBER Petamo GHY 133N) the pinion

teeth, the seal ring rotary seating and the ring itself, and assemble

carefully,

paying particular attention not to damage the seal

ring lip due to an accidental impact with the pinion toothing

.

Servo gear reducer type R

(servo motor coupling with bell and torsionally stiff coupling)

–

Worm servo gear reducer R V, R IV

–

Helical servo gear reducer R 2I, R 3I

–

Bevel-helical servo gear reducer R CI, R ICI

The servo gear reducer

type R input face has

a flange (

bolts not

included

) for servo

motor mounting and a

torsionally stiff coupling.

A half-coupling hub is to

be fitted onto the servo

motor keyless shaft end (if present, remove it; see fig. 1). In case of

high starts/hour and heavy loads, it is necessary to request the non-

standard design

«Coupling with keyway»

.

All mounting surfaces (shafts, bores, keys and keyways), must be

clean and free of burrs, nicks and dents.

Check the servo motor shaft diameter, coupling bore diameter, key

and keyway dimensions and tolerances.

All coupling bores are machined to tolerance H7

.

Assembling clearance between the servo motor shaft diameter and

half-coupling hub diameter has to be maintained within 0,01 and

0,05 mm.

A light coating of oil is recommended to ease the mounting process

and will not affect the clamping force of the hub.

Do not use molybdenum disulphide or equivalent lubricants.

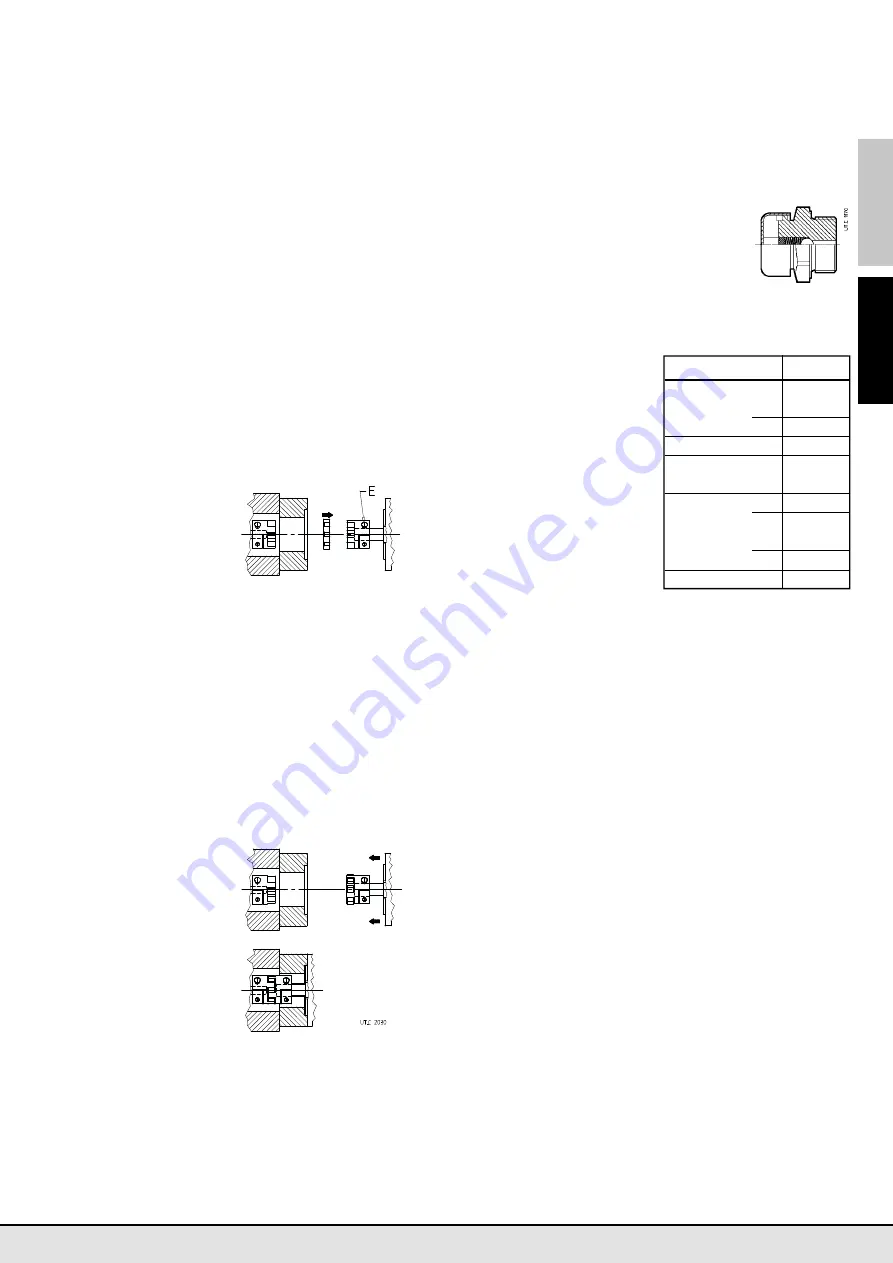

Insert the half-coupling onto the servo motor shaft, as shown

in fig. 1, abutting with elastomer ring seat

.

Tighten the clamp

screw

E

, using a

dynamometric wrench,

to the appropriate

torque stated in the

table

1)

(see page 24).

Clean the elastomer

ring and the seats into

the coupling hubs

and apply a light film

of oil to facilitate the

assembly process, see

fig. 2 (use polyurethane

compatible lubricants

such as e.g. vaseline).

Insert the elastomer ring

(fig. 2) and assemble the

servo motor on the servo gear reducer, tightening the screws (fig. 3)

on the servo motor flange.

The achievement of the zero angular backlash is ensured by

the squeezing of the elastomer ring interposed between the

two parts of the coupling

.

1) In some cases, a spacer to be interposed between the half-coupling and the servo

motor shaft shoulder is provided

9.6 - Bearings

Since there are many different types of bearings in a gear reducer

(roller, tapered roller, straight roller, etc.) and each bearing works

fi g. 1

fi g. 2

fi g. 3

with different loads and speeds depending on the input speed, the

nature of the load of the driven machine, the transmission ratio,

etc., and with different lubricants (oil bath, oil splash, grease, oil

circulation, etc.), it is not possible to define any periodical mainte-

nance and replacement of bearings in advance.

If a precautionally maintenance is required,

undertake periodical

checks to verify noise level and vibration with the help of

appropiate diagniostic equipment and instruments

. If the

measured values worsen even slightly it is necessary to stop gear

reducer or gear motor and after having inspected inside the unit

replace the bearings which are subject to breakdown.

9.7 - Metal filler plug with filter and valve

When the gear reducer or gearmotor (size ≥ 100)

is equipped with metal filler plug with filter and

valve (see fig. beside), in order to clean it, it is

necessary to unscrew it from the gear reducer

(preventing any debris or other foreign items

from entering the reducer, disassemble the

cover, wash it with solvent, dry with compressed

air and reassemble it).

This operation is to be made according to environment conditions.

10 - Sound levels

Most of the Rossi product

range is cha

racterised

by

sound pressure levels L¯

pA

(mean value of mea-surement,

assuming nominal load and

input speed

n

1

= 1 400 min

-1

,

at 1 m from external profile of

gear reducer standing in free

field on a reflecting surface,

according to draft proposal

ISO/CD 8579)

lower or equal

to 85 dB(A).

The table indicates the pro-

ducts which

can exceed

a.m.

threshold. For further informa-

tion about sound levels of every

single product see Rossi tech-

nical catalogs.

Machine/Train of gears

i

N

Size

Helical

R I

<

3,15

>

160

>

4

>

200

R 2I

all

>

320

R 3I

all

>

400

R 4I

<

160

>

500

>

200

>

630

Bevel helical

R CI

all

>

320

R C2I <

63

>

400

>

71

>

500

R C3I

all

>

630

Bevel helical

R C

1

>

250