h7583 tenoning Jig

-13-

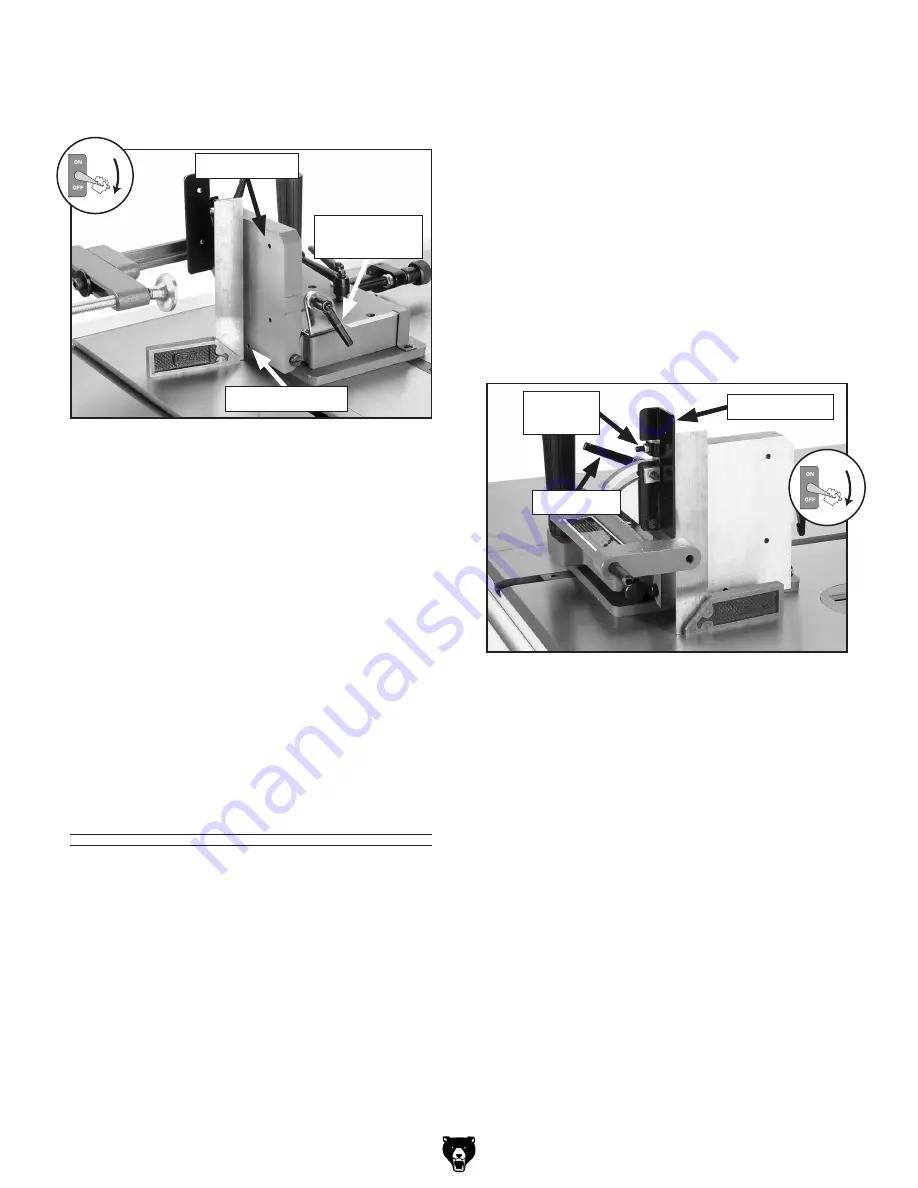

5. thread the positive stop set screw far enough

away from the side support so that it will not

interfere with the next step (see

figure 14).

6. position the machinist's square flat on the

table and up against the jig side support.

7. loosen the support lock lever, position the

side support flat against the machinist's

square, then, without moving the support, re-

tighten the lock lever.

8. remove the square and re-tighten the stop

set screw until it just meets resistance. the

90° positive stop is now set for quick perpen-

dicular positioning of the side support.

back Support

adjustment

To adjust the back support:

1. disConnECt tABlE sAW FroM

poWEr!

2. Completely lower the saw blade so that it will

not interfere with the measurements.

3. Clean away any debris from the table or jig

that could affect the measurements, then

insert the jig all the way into the miter slot.

4. loosen the jam nut on the positive set screw,

then back off the set screw to allow adjust-

ment to the back support (see

figure 15).

figure 14. Adjusting the side support

perpendicular to the saw table.

side support

side support

lock lever

stop set screw

in this procedure you will adjust the back support

perpendicular to the saw table, then set the 90°

positive stop so the back support can be returned

to the perpendicular position after an angle cut.

5. position the machinist's square flat on the

table and up against the back support of the

jig, as shown in

figure 15.

6. loosen the support lock lever, position the

back support flat against the machinist's

square, then, without moving the support, re-

tighten the lock lever.

7. remove the square and re-tighten the stop

set screw until it just meets resistance, then

re-tighten the jam nut to secure the setting.

the 90° positive stop is now set for quick per-

pendicular positioning of the back support.

figure 15. Adjusting the back support

perpendicular to the saw table.

Back support

stop set

screw

lock lever