Model G0832 (Mfd. Since 04/17)

-29-

SECTION 6: MAINTENANCE

For optimum performance from your machine,

follow this maintenance schedule and refer to any

specific instructions given in this section.

Daily Check

•

Loose mounting bolts.

•

Damaged knives.

•

Worn or damaged wires.

•

Any other unsafe condition.

Monthly Check

•

Clean chains and sprockets of dust, wood

chips, and old grease.

•

Lightly coat chains and sprockets with NLGI#2

grease (see

Page 30).

•

Lubricate elevation leadscrews with spray

lubricant (see

This Page).

•

Check V-belt for tension, damage, or wear

(see

Page 33). Also, ensure belt is clean and

free of oil or grease that could cause it to slip.

•

Remove cutterhead guard and fan cover, and

thoroughly clean built-up sawdust and chips.

Schedule

To reduce risk of shock or

accidental startup, always

disconnect machine from

power before adjustments,

maintenance, or service.

Cleaning the Model G0832 is relatively easy.

Vacuum excess wood chips and sawdust, and

wipe off the remaining dust with a dry cloth. If any

resin has built up, use a resin-dissolving cleaner

to remove it.

Cleaning &

Protecting

There are four primary systems that require peri-

odic lubrication: the cutterhead elevation lead-

screws, the feed roller chain drive, the table height

chain, and columns. Clean the components in this

section with an oil/grease solvent cleaner or min-

eral spirits before applying lubrication.

Elevation Leadscrews & Columns

Items Needed

Qty

Type ............................. G4682 Dry Coating Lube

Frequency ................................................Monthly

Hex Wrench 4mm .............................................. 1

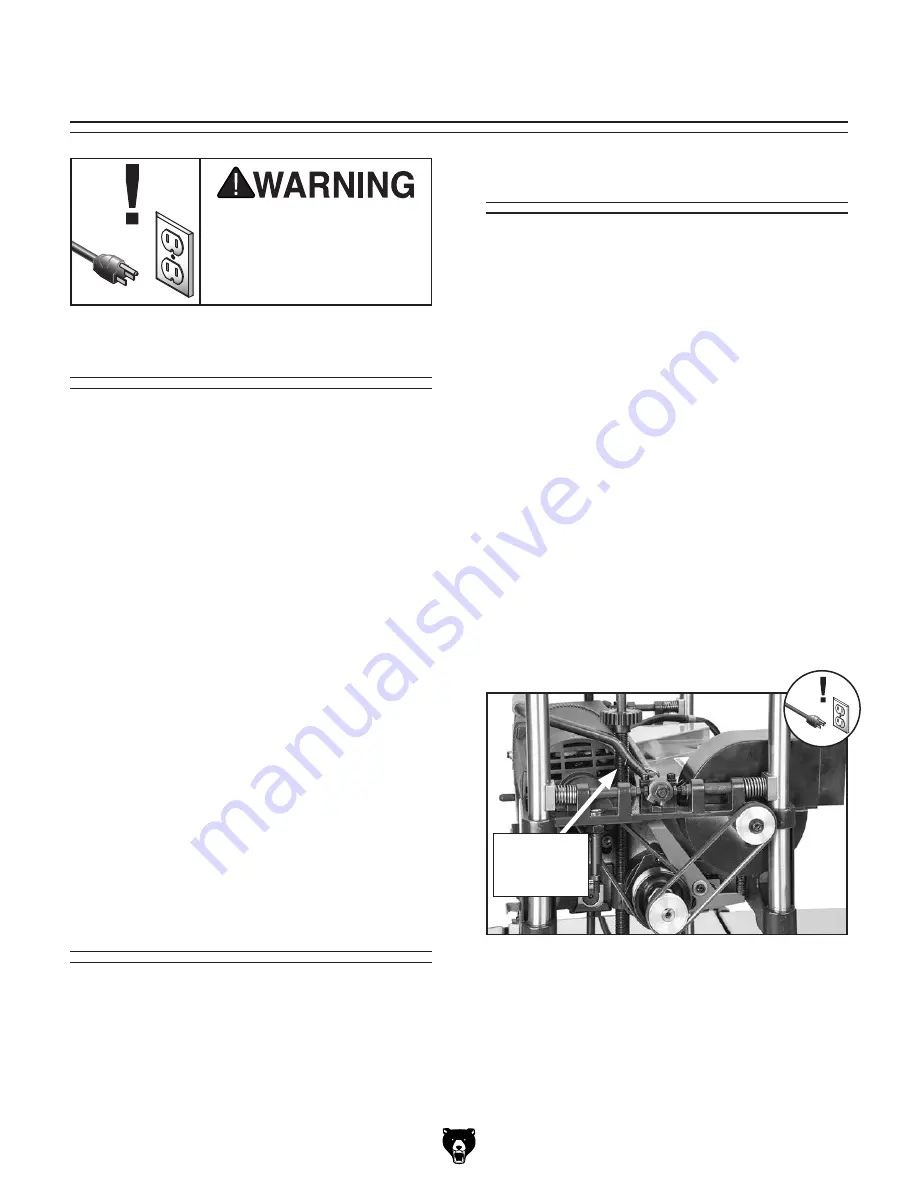

To lubricate elevation leadscrews & columns:

1. DISCONNECT MACHINE FROM POWER!

2. Lower headstock fully and remove side

panels to expose (2) leadscrews.

3. Vacuum chips and dust off of leadscrews

(see

Figure 32).

Lubrication

4. Use mineral spirits, stiff brush, and shop rags

to remove old lubricant.

5. Spray lubricant onto each leadscrew and

column, taking care to keep it off belts. Move

cutterhead up and down to evenly distribute.

Figure 32. Location of cutterhead elevation

leadscrews.

Elevation

Leadscrews

(1 of 2)

Summary of Contents for G0832

Page 52: ......