-42-

G0803

(Mfd. Since 09/15)

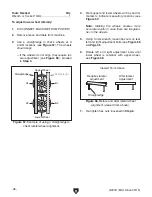

Checking/Adjusting

Belt Tension

To ensure optimum power transmission from the

motor to the blade, the belt must be in good condi-

tion and operate under proper tension.

Belt tension should be checked at least every

month—more often if the bandsaw is used daily. If

the belt shows signs of cracks, fraying, and exces-

sive wear, replace it as instructed in

Replacing

Belt on Page 43.

Checking Belt Tension

1. DISCONNECT MACHINE FROM POWER!

2. Open lower wheel cover.

3. Check belt condition and deflection. The belt

is properly tensioned if there is approximately

1

⁄

4

" deflection. Deflection is checked by push-

ing belt with moderate pressure, as shown in

Figure 50, and noting how much it moves.

— If the belt is not properly tensioned, per-

form the

Tensioning Belt procedure.

Pulley

Deflection

Pulley

Figure 50. Checking belt tension.

Approximately

1

⁄

4

"

Tensioning Belt

Tool Needed

Qty

Hex Wrench 6mm .............................................. 1

To properly tension the belt:

1. DISCONNECT MACHINE FROM POWER!

2. Loosen motor mount cap screws shown in

Figure 51.

3. Push motor to the right (as viewed from back

of machine) until you feel moderate tension,

then re-tighten both cap screws.

4. Check belt tension. If necessary, repeat

Steps 2–3 until there is approximately

1

⁄

4

"

deflection in the belt.

5. Close wheel cover.

Figure 51. Location of motor mount cap screws

used for adjusting belt tension.

Motor Mount

Cap Screws

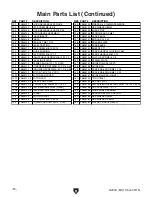

Summary of Contents for G0803

Page 56: ...54 G0803 Mfd Since 09 15...

Page 60: ......