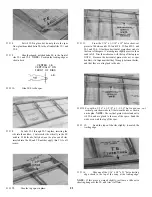

D 6. Using an Xacto knife, cut the hinge slots in the

wing and ailerons.

D 7. Temporarily attach the ailerons to the wing with

the hinges, but do not glue until after the wing has been

covered!

INSTALL AILERON SERVO AND HORNS

NOTE: Install the aileron servo in the bottom of the wing!

D 1. Cut an opening in the fiberglass and bottom sheeting for

your servo. CAUTION: Do not cut into the wing spar or

shear webs!

D 2. Remove a sufficient portion of the center rib and

the W-1 ribs to fit your servo. NOTE: The die-cut openings

will have to be enlarged and deepened. (A Dremel Moto tool

with a 1/8" router bit is excellent for this, but it may also be

done with an Xacto knife and a long-nose pliers). The servo

must be installed as deep into the wing as possible.

D 4. Mount the servo using the screws provided with

your radio.

NOTE: Because the nylon horn mounting screws pass through the

inboard aileron hinges, we glued only these two hinges into the

ailerons (permanently), mounted the horns (temporarily), and

worked around these hinges when covering the ailerons. If you do

not want these hinges in the way when covering, we suggest that you

wait until the airplane is covered and the hinges glued in before

installing the nylon horns.

D 5. Hold the nylon horns on the bottom of the ailerons

in the locations shown on the plan, and mark the locations

of the mounting screws.

D 3. Make two servo rails from the 1/8" ply die-cutting

scrap, and glue in place. (See the side view of the aileron

servo installation on the plan).

D 6. Drill 5/32" holes through the ailerons (and

hinges). Put a drop of thin CA into each hole (to harden the

balsa), wait until the glue hardens, then re-drill the holes.

D 7. Temporarily mount the nylon homs with the 2-56

x 5/8" screws and nylon nutplates. You may cut off the

portion of the screws that protrude through the nutplates.

NYLON HORN AND NUT PLATE

2 - 5 6 x 5/8" SCREW

26