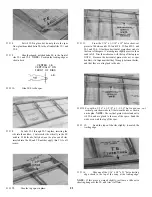

HINGE

o o

0 0

3/8"

piece of sandpaper held with your fingers, rather than a

sanding block. Do not sand the centerline of the hinge

material.

TEMPORARILY INSTALL HINGES (Do not glue the hinges at

this time).

1. You'll need eight of the hinges you just made, plus

an Xacto knife with a No. 11 blade.

D

D

2. If you have not already done so, draw an accurate

centerline on the trailing edge of the fin and stabilizer.

D

D

3. Using a ruler and a ball point pen, draw lines

dividing the hinge material into sixteen 3/8"-wide seg-

ments.

4. Drill four 1/16" holes in each of the hinge seg-

ments as shown on the plan. Use a wood block as a backing

when drilling these holes. After drilling, lightly sand the

hinges again to remove any rough edges caused by drilling.

6. Cut the hinges apart with a scissors on the lines

you previously drew. Also snip off a small piece of each

comer.

(See sketch at top of next column.)

D 5. Fold the hinge material back and forth a few times

to "condition" the hinges.

D

3. Lay the fin and stabilizer on the plan and mark the

hinge locations on the trailing edges.

D

4. Now, while holding the elevators in place against

the stabilizer trailing edge, transfer the hinge locations over

to the elevator leading edge. Repeat this process to mark

the hinge locations on the rudder.

D

NOTE: The hinges supplied with this kit are thin enough that they

can be inserted into a slot made with an Xacto knife. Most other

hinges require you to use a hinge slotting tool. The following steps

describe how to easily cut the hinge slots with an Xacto knife.

CAUTION!!!: You must use extreme care when cutting hinge

slots with an Xacto knife, to avoid cutting yourself! If the

balsa part breaks while you are pushing on the knife, the blade

could go into your hand before you know it! A good precau-

tion is to wear leather gloves while performing the following

steps.

16