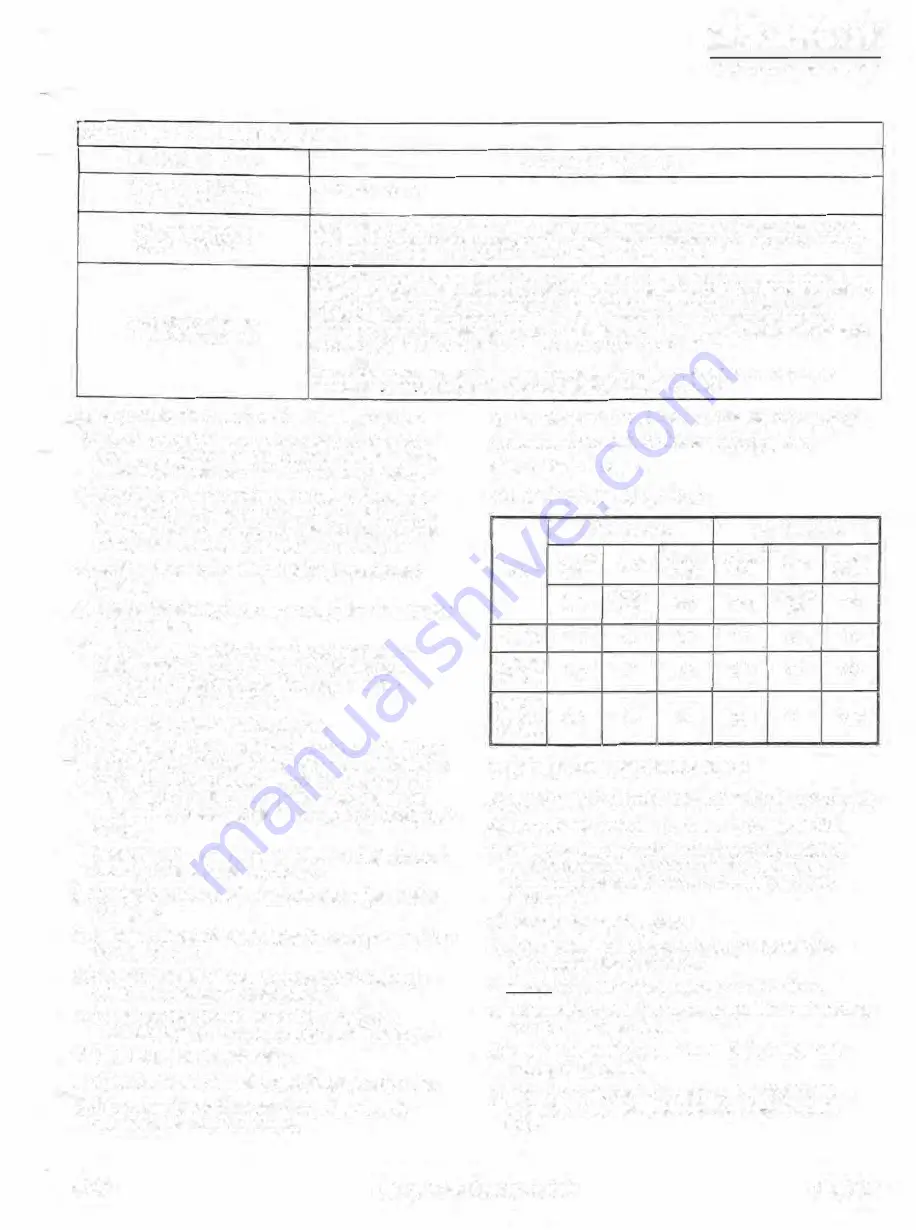

T ABLE 7..3 ROTOR END PLAY TOLERANCES

MEASUREO END PLAY

(0.0005

to

0.0010 inch)

0,0127 to 0.02-54 mm

Bearings are sound.

CONDITlON AND ACTION

GRB&Sa

8EDENINQSVOORSCHRIFT,11ETREBSAHL.EfflJNC

IN$Tl>llCTIOOI IWltW.MANIIELO'IIISTRUCT101<

(0,010 to 0.0020 inch)

Beaöngs are questionable. Remove the coupllng, pip1ng, shaft seal and outJet cover as in section 7, 11.

Inspeel the out board bearing raceway and rolling elements for visible damage (eg pil marks, scoring or

0.0254 to 0.0508 mm

loose cagesJ. Re•inspect

every

1,000 hours

if

no sign of pitting

or

scoring,

Remove the coupling, piping,

shaft

seaJ and outlet cover as fn paragraph 7.11, Inspeel Ine

outboa-rd

bearing raceway and rolling elements for vlslble damage (eg pit marks, scoring or lease cages). Push the

rotor by hanc;I (501b or 200 Non the lever) to the discharge end of the compressor. Measure the

(0.0020 inch and above}

clearance between the end face of the rotor and the discharge housing by inserting feelèr gäuges

0.0508

mm and above

through thè discharge port with the capacity controf sfîde valve in the maximum position. This clearance

shoi,Jld be (0.002 inch to 0.005 inch) 0.0508 mm to 0.127 mm for all models.

Contact Grasso with the measurements

of

both the end play and the rotor wfral clearance and the

Ci!:!Dif;m:S'isu :ie[iill num�t as the thrust bearings may have to be replaoed.

a) Carry out the shutdown procedure in paragrap.h 7_.3_

,) Referring

to

fig.

7.5.

remove the male rotor inlet bear

ing cover including 0-ring by removing the bolts. Use

screwdriver to part the cover from the inlet housing.

c) lnstall an eye bolt from table 7.4 in one of the tapped

holes whic� is exposed on the end of the balance pis

ton. Screw rn an eye bolt from table 7.4 in place of

the

screw taken out of the male rotor inlet bearing cover.

d) lnstall a second eye bolt from table 7.4 into the inlet

housing.

e) lnstaH a (three inch) 76.2 mm contact point extension on

a dial indicator.

f)

Mount a magnetic dial indicator on the compressor

casting with the contact point of the dial indicator

touching the male or female rotor, depending on

which rotor is being checked.

g) Set the dïal indicator reading to zero.

h) With a (3/4 inch) 19 mm diameter by (one

toot)

305 mm

1

long bar placed through both eye bolts and by using the

,

eye bolt in the inlet housing as a fulcrum, a,pply hand

force [approx.

(50

Ibs)

220 NJ

using a back and forth

movement to create end play {see figure 7.5 for a typical

set up).

1) Read the end play movement on the dia! indicator when

the hand force is applied to the bar.

j) Compare the rotor end play with the tolerances in table

7.3 above.

k) After one rotor is checked, follow the same procedure for

the second rotor_

1) Reassemble parts with

new

gaskets and 0-rings (eg

cover and (fe)male rotor infet bearing).

m) Tighten the ferry head screws to the torques tor

Grade 8 condition B fasteners in table 7 .1 in para. 7.4.

n) Close tne pressure satety valve.

o) Open the suction stop valve and discharge stop valve.

,,

lf the compressor is fitted with an economizer port,

open the economizer stop valve.

q) Reconnect the control cabinet to the electric supply line.

r) Reconnect the starter to the electric supply line.

s) Start the compressor

.

T ABLE 7.4 EYE BOLT DETAILS

Rotor eye bolt

Housing eye bolt

Thread

Pitch

Shank

Thread

Pitch

Shank

Model

dia.

length

dia.

length

inch

thread/

inch

inch

thread/

inch

inch

inch

GSL65

5/16

18

3.5

1/2

13

1.5

GSL85

3/8

16

4.0

1/2

13

1.5

GSL125

GSL165

GSL180

3/S

16

5.0

5/8

11

1.75

GSL240

7.10 THRUST BEARING INSPECTION

A) REMOVAL OF OUTLET END COVER (refer to figure 7_6)

a) Carry out the shut down procedure in paragraph 7

.3.

b) Place the capacity control slide valve in the maximum

position by rotating the output shaft clockwise (ma

nually

or

with

a suitable wrench after pulling out the

black knob).

c} Remove the coupling guard.

d) Remove the coupling spacer (incl. plate packs), the

rotor coupling flange and key.

e)

Do not

move either the compressor or the motor.

f)

Remove the high discharge temperature thermostat bulb

from the discharge pipe.

g} nemove the di�ch0r9e pipe betweçn the;

oomprc;,;,or

and the oil separator.

h} Remove the discharge pressure stop valve trom the

outlet cover and disconnect the shaft seal oil supply

line.

92.01

Compressor Package GSLP

Page

7.7