2 – 4

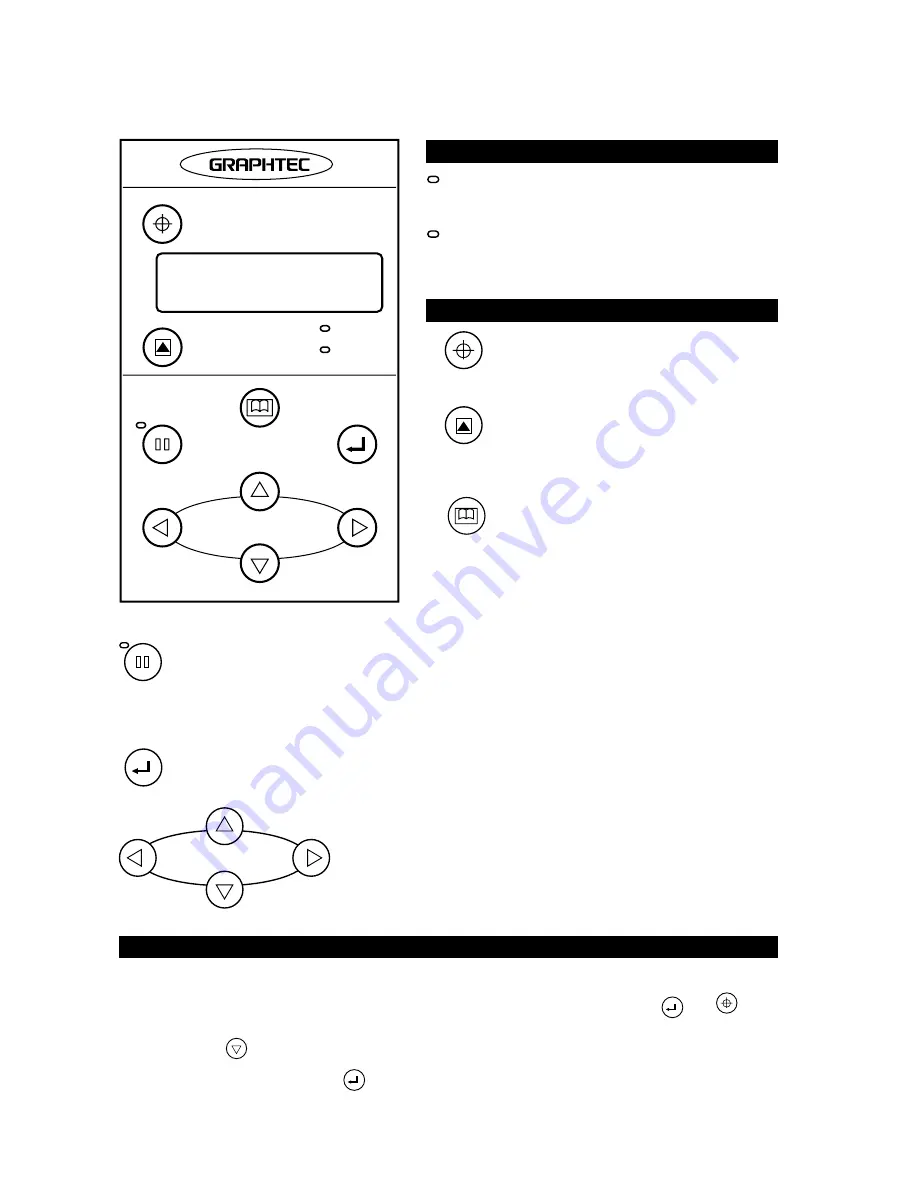

2.3 Control Panel

Lamps

POWER

: Remains lit while the cutting plotter is being

supplied with power.

PROMPT

: Lights upon the receipt of plot data speci-

fying a coordinate point outside of the ef-

fective plotting area.

Panel Keys

F1/ORIGIN

: Press this function key to reposi-

tion the origin point or to select

a menu function in PAUSE status.

F2/TEST

: Press this function key to run a

cutting test for checking the cut-

ting conditions or to select a menu

function in PAUSE status.

NEXT PAGE

: Press this function key to switch

through COND1 to COND4. When

a menu is being displayed in

PAUSE status, press this key to

proceed to the next menu.

PAUSE

: This key functions differently according to the current operating status.

Press it once to enter the PAUSE status and light up the PAUSE lamp. Press it again to cancel

the PAUSE status and turn off the PAUSE lamp.

Press this key when you wish to discontinue cutting or plotting or set functions at menus on

the display panel.

ENTER

: After setting a cutting or plotting condition, press this key to register the setting.

POSITION

: These keys function differently according to the current operating

status.

When the cutting plotter is not in PAUSE status, they are used

to move the pen carriage.

When the cutting plotter is in PAUSE status, they are used to

change the settings of functions at menus on the display panel.

Setting the Multilingual Display

Your cutting plotter’s display can be set to one of six different languages: English, French, German,

Italian, Japanese, or Spanish. To access the language selection menu, hold down the

ENTER

and

F1/ORIGIN

keys while turning on the power. Hold down the keys until a two-line language display menu appears.

Next, press the

POSITION key to move through the six language selections. When the desired

language is displayed, press the

ENTER

key to register your selection.

F1 / ORIGIN

F2 / TEST

PAUSE

ENTER

POWER

PROMPT

NEXT PAGE

POSITION