LL200 Compressor Installation

12

332230T

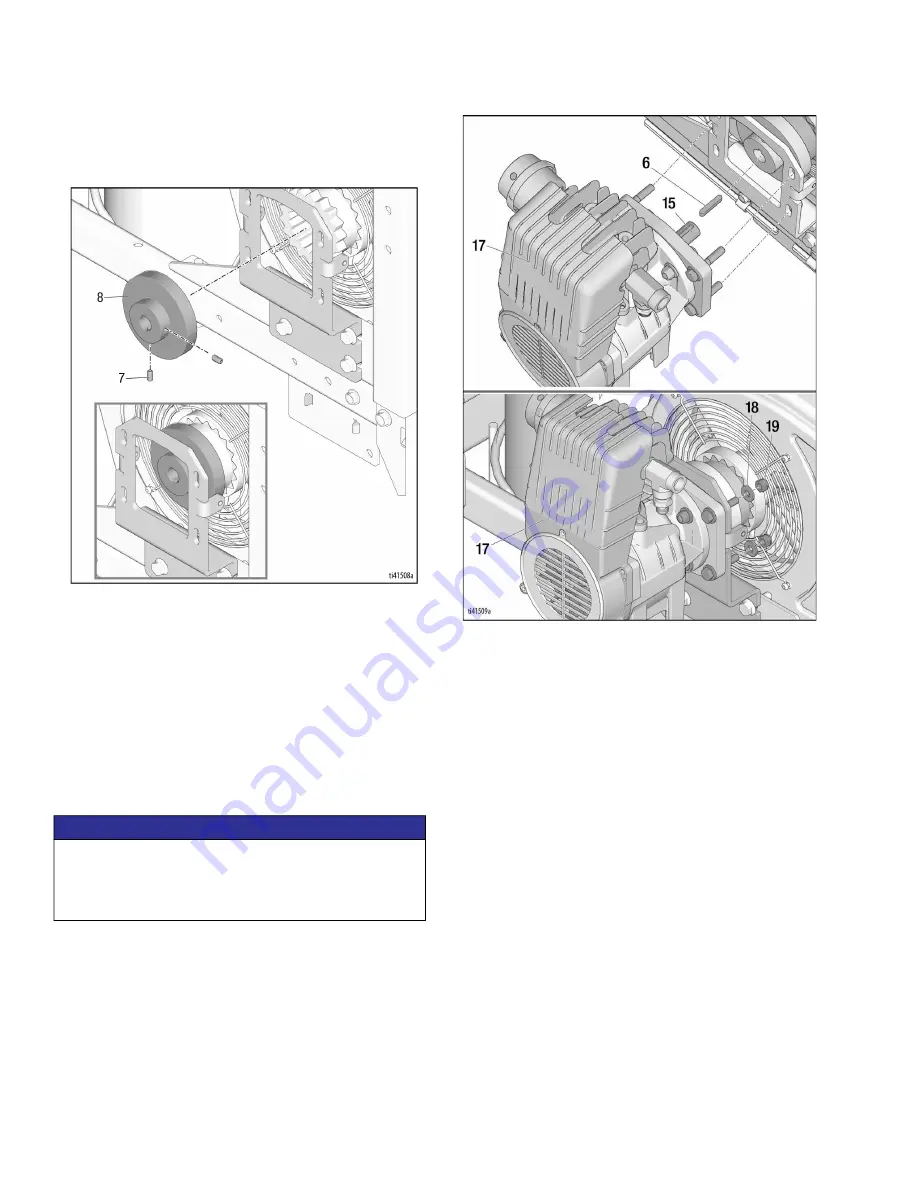

16. Start two set screws (7) into second coupler (8).

Slide coupler (8) over flex insert (9). Coupler (8)

should stay in position, if not it may need to be held

until the next step.

17. Ensure keyway on coupler shaft (15) is on top,

rotate as necessary. Place second key (6) in

keyway of coupler shaft (15). Align keyway in

coupler (8) to receive coupler shaft (15) and key (6).

Aligning all four studs (16) with associated vertical

slots, slide compressor assembly (17) into

mounting bracket so that coupler shaft (15) inserts

into coupler (8), ensure key (6) stays in place. Install

four washers (18) and four nuts (19) onto four studs,

tighten until slightly loose to allow for vertical

adjustment.

18. Horizontal Alignment: hold compressor assembly

(17) such that when viewed from above both

couplers (8) and flex insert (9) are aligned axially.

When properly aligned, tighten mounting bracket

bolts (11) to frame to 23-27 ft-lbs (31-37 N•m).

Horizontal alignment is now complete.

NOTICE

Performing the following step incorrectly may result in

improper alignment of the two rotating couplers. This

may cause premature wear and require replacement

of the flex insert (9).